Wait! Get exclusive access!

Subscribe to our newsletter for priority access to the latest trends, updates, and exclusive content from Aptyx. Don't leave without staying informed!

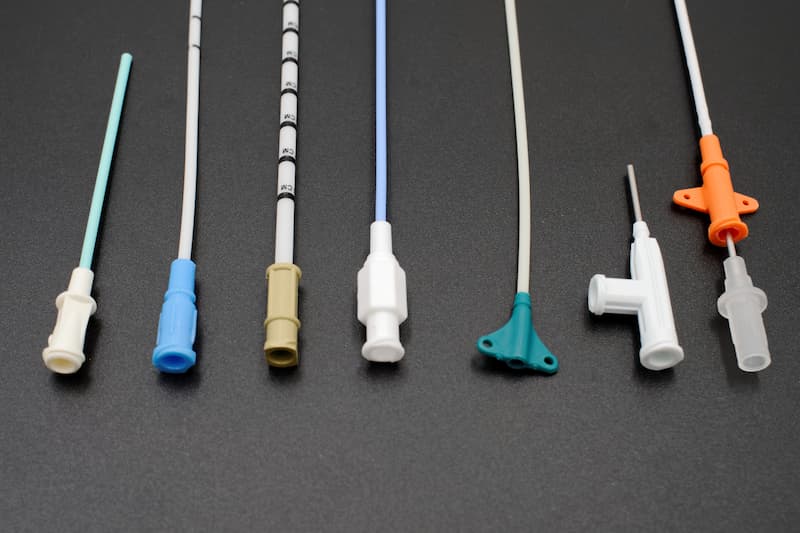

PRECISION CUSTOM EXTRUSION & core MANDREL FOR CATHETERS AND BEYOND.

Supporting most thermoplastics, including:

Stripe, radiopaque, jacketed, co-extruded products, single and multi-pass layered extrusions

0.2 to 25mm (.008 – 1”) – varies by material & style

We have over 10 years experience supplying high-quality core mandrel for demanding applications to global leaders.