Experts in

mission-critical manufacturing.

We create smart solutions to complex challenges.

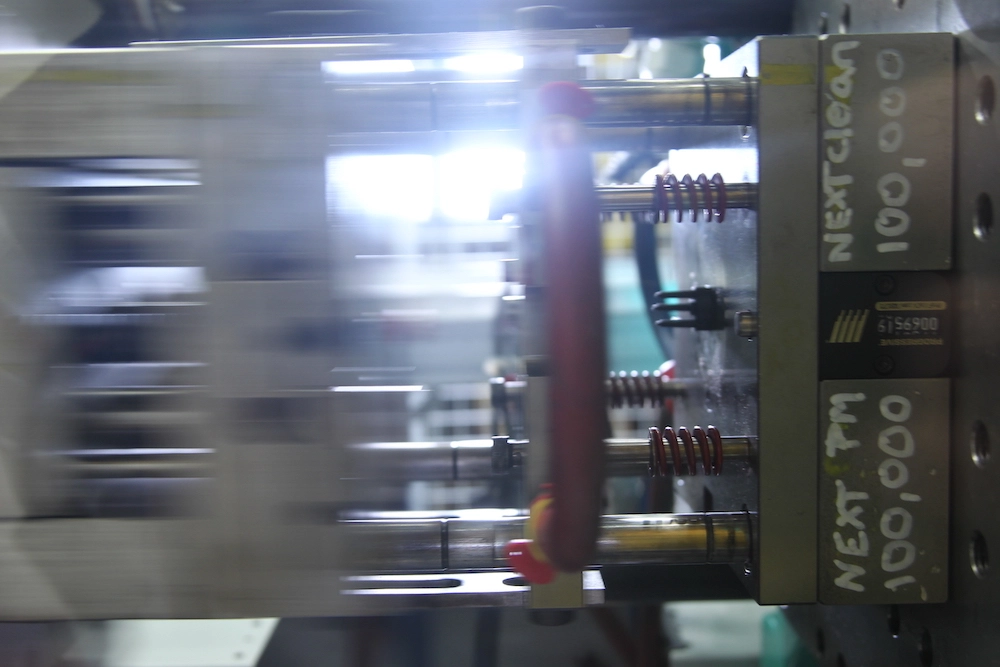

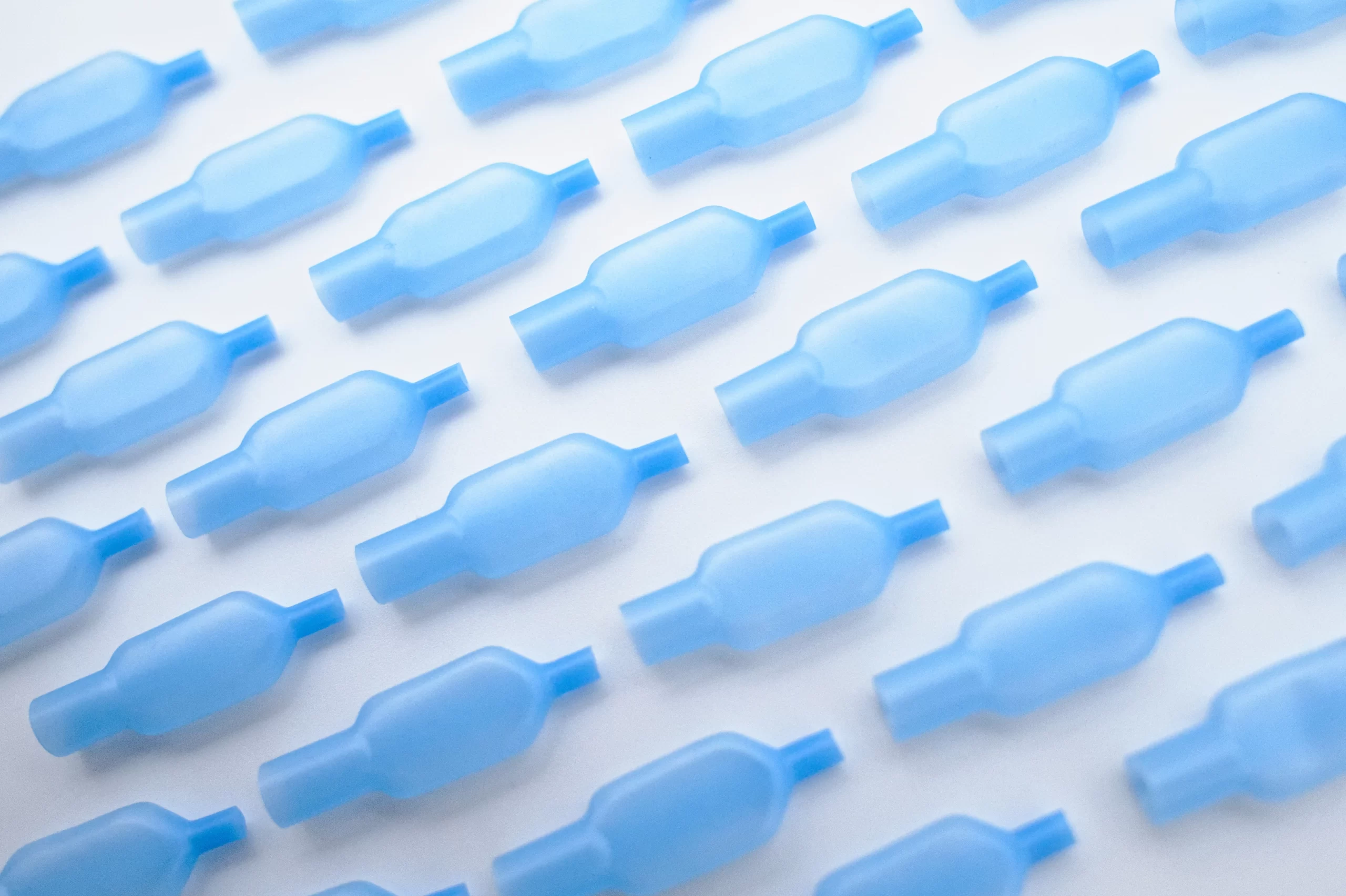

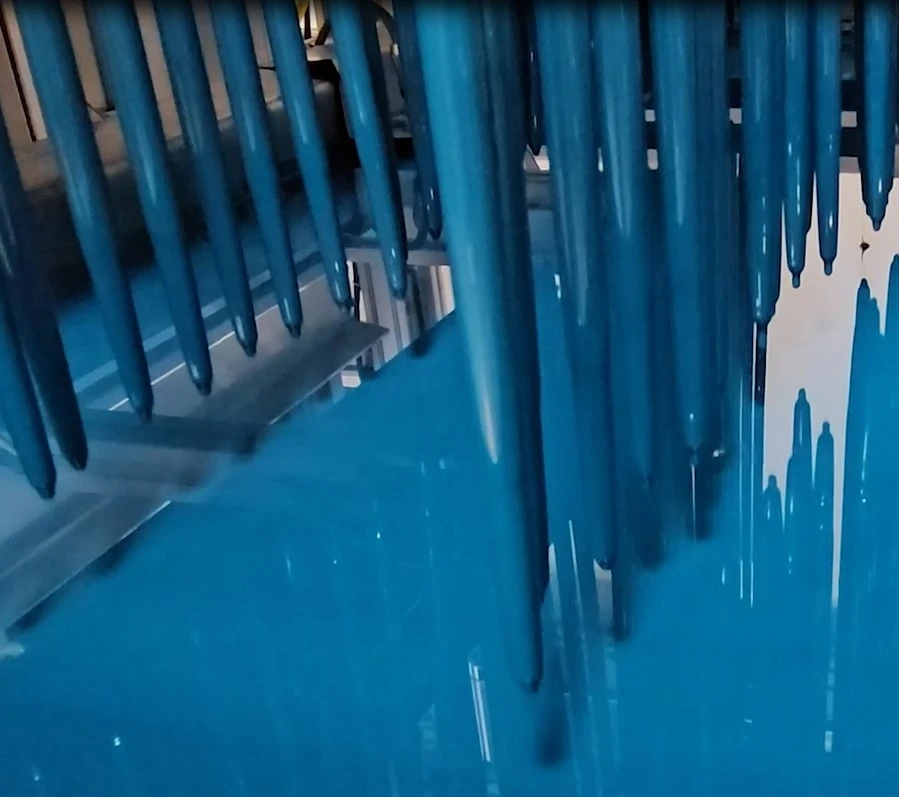

At Aptyx, your products are our purpose. You can rely on us to deliver quality, complex manufacturing solutions at scale to bring your mission-critical components and devices to life. Our team solves tough manufacturing challenges so that you can create more good things in the world and bring more innovative and life-changing solutions to people who need them. We make it happen through our integrated, comprehensive capabilities including engineering, molding, extrusion, coatings, and assembly.

Complex manufacturing, when and where you need it.

Meet Aptyx. A new name backed by 70 years of expertise.

- Skilled, keenly intelligent

- Natural ability to learn or perform in a specific area

- Ability to deliver

- Superior quality of work

- High achieving

- Excelling in merit

About Us

Making it happen is the way we do business. It takes an unwavering focus on quality. It takes deep expertise in engineering and know-how in molding, extrusion, coatings, and assembly. It takes integrity in action and a growth mindset: always being on the lookout for what’s possible.

We believe in a collaborative approach to complex manufacturing because we know our success depends on your success. We do it because the products you make matter.

MISSION

VISION

VALUES

Innovative thinking, agile decision making, and big ambition is in our DNA. We find opportunities and solve problems with entrepreneurial speed and accountability.

Every day, every line, every job starts and ends with a rigorous and unrelenting focus on the quality and excellence of our work, including the safety and well-being of our team members.

You can rely on us to deliver with integrity, truth, and accountability no matter what challenges arise. We’ll know the answer, find the answer, or solve any problem with expediency and a commitment to getting the job done right.

We’re in the business of building long-term, trusted partnerships based on transparency and clear communication at every touchpoint inside and out. We speak up, respect, and support each other.

We look for what’s possible. We’re curious and strive to learn something new each day. We are open minded and celebrate the diversity, expertise, and experience each of us contributes to the important work we do for our customers.

Global reach. Local touch.

Global manufacturing, at your service.

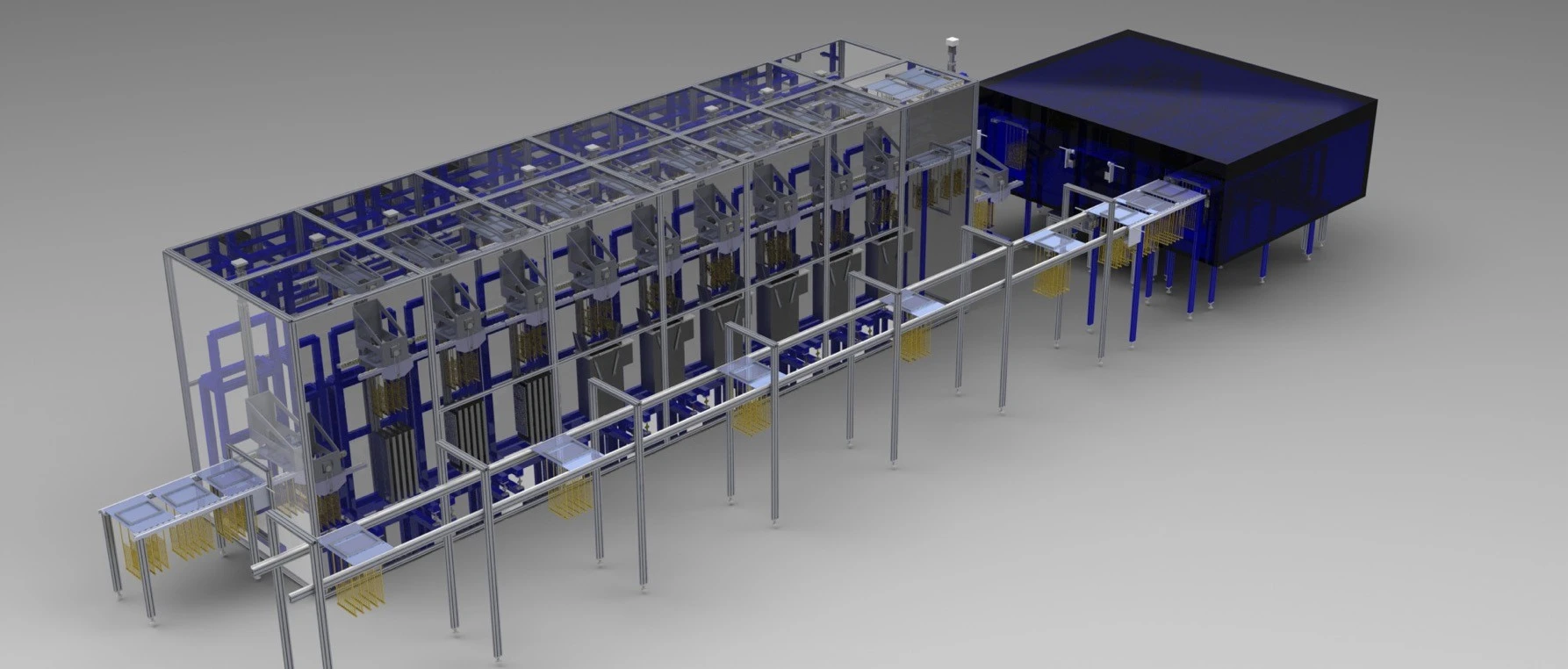

Our growing global network brings you convenience and flexibility. Our manufacturing facilities in four countries offer specialized technologies and capabilities as well as ISO 13485 and ISO 9001 certifications to meet the specialized needs of demanding industries. With domestic, near-shore, off-shore, and low-cost manufacturing capabilities and automation expertise, our team can meet the unique demands of your mission-critical complex component or device.

United States

Canada

Mexico

China

Serving mission-critical

markets.

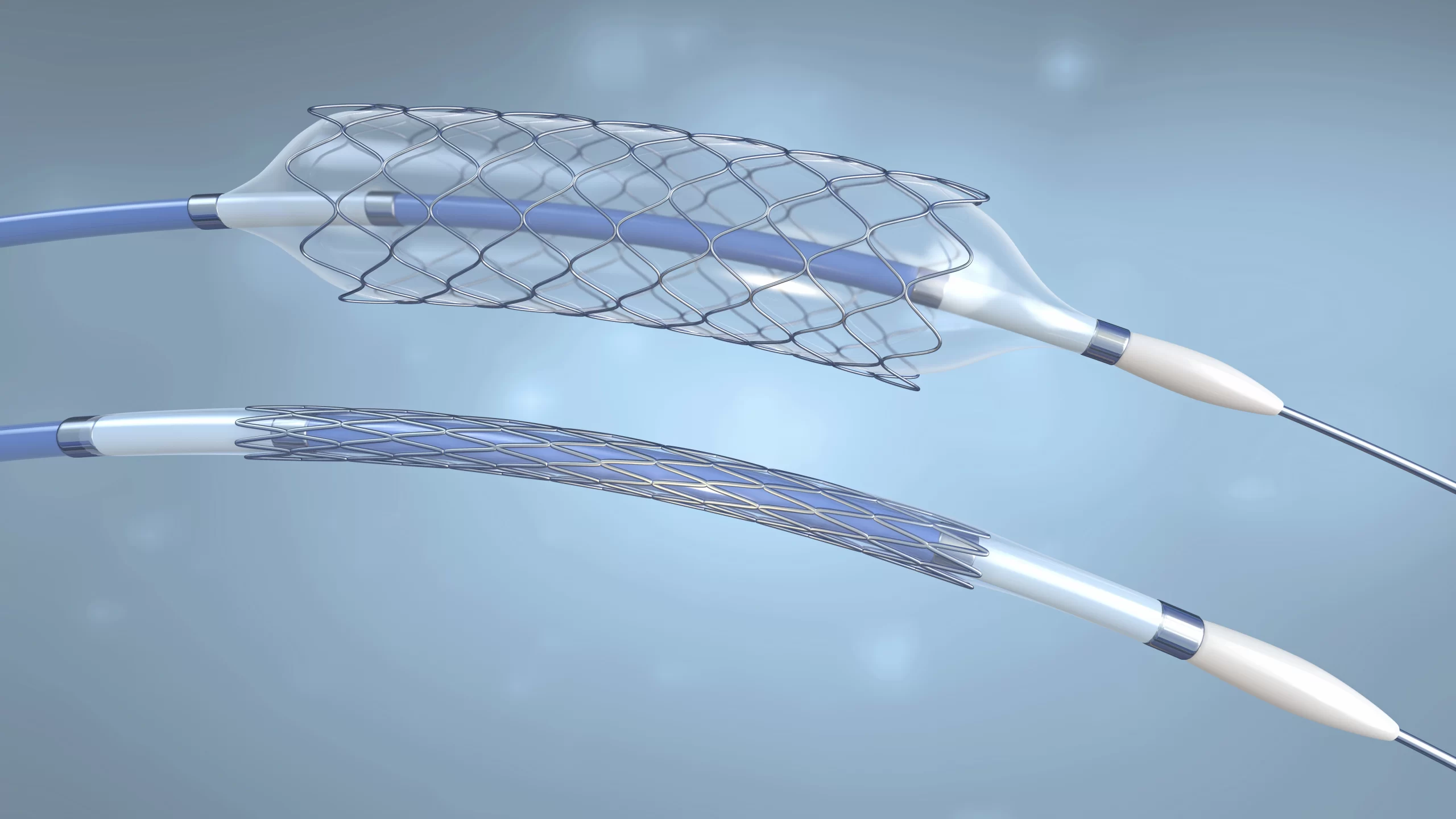

MEDICAL DEVICES & LIFE SCIENCES

Industrial

AEROSPACE & DEFENSE

Energy

Environmental, Social and Governance (ESG)

We take environmental, social and governance (ESG) policies very seriously and through these policies we clarify our goal of being a trusted employer, partner, and contributing member of society just as we have over the past 70 years through our portfolio of pioneering companies.

Environmental

From our supply chain to our physical facilities, we search for ways to conserve energy resources, including a focus on recycling programs that seek to reduce and eliminate landfill waste. These programs are also made available to our associates to encourage and promote an environmentally responsible local community. We monitor our progress and track key metrics focused on energy conservation and reduction.

Social / Ethics

We feel a deep responsibility to the communities we serve worldwide as well as to our customers, competitors, distributors, and suppliers. We are committed to product safety, efficacy, and ethical planning and management of resources. As a producer of many medical grade products, we feel a special ethical responsibility to produce the highest quality products. We are committed to workforce diversity, equity, training, and a culture of collaboration and inclusion.

Governance

We provide our shareholders and investors with honest and ethical financial accountability and provide total transparency to regulators. We provide financial support for continuous improvement initiatives that target business growth, six sigma/lean manufacturing improvements, and waste reduction.

Leadership Team

Timeline