Your manufacturing ally –

from idea to execution

Precision manufacturing when quality, speed and expertise are essential

At Aptyx, your mission-critical products are our purpose. It’s why we exist. It’s why we do business with straight talk, speed, and a commitment to quality. We believe in a collaborative approach to complex manufacturing because we know our success depends on your success. Bring on your tough design and manufacturing challenges and most innovative ideas. We’ll bring our deep expertise in engineering, molding, extrusion, coatings, and assembly. Together, we make it happen.

Expert solutions.

Easy collaboration.

Key benefits of partnering with Aptyx.

When we ask customers what they want from a manufacturing partner, several themes emerge. They want a reliable, collaborative partner who can roll up their sleeves and help them solve problems, not just make widgets. They want a partner who will actually listen to understand their needs and communicate proactively, openly, and honestly. They want a partner with a proven track record that can speed their products to market, without compromising quality. At Aptyx, we strive to be that kind of partner. We make it happen, so you can make it happen.

Entrepreneurial mindset

An entrepreneurial mindset is part of our DNA: Get it done. Don’t settle. Take action. Aptyx was formed by bringing together select pioneering companies that have pushed boundaries and disrupted the status quo. We’ve woven together the capabilities and strengths of these entrepreneurial companies into one organization dedicated to engineering and manufacturing smart solutions for complex challenges. We collaborate with you to help transform your innovative ideas into market success.

Speed to market

We understand that anything that causes a delay in getting your product to market on time can potentially put lives and livelihoods at risk. That’s why we move at entrepreneurial speed, leveraging decades of experience in highly regulated industries to skillfully get things done. Because proactive, transparent communication is key for speed to market, we assign a dedicated project engineer to each program to ensure alignment from start-to-finish.

Quality

An unwavering focus on quality is the cornerstone of our organization. Our ISO 13485-certified and FDA-registered medtech manufacturing facilities have developed robust Quality Management Systems to ensure we meet regulatory requirements and manufacture devices with consistently high quality. Our certifications include ISO 9001 and ISO/TS 16949 to comply with stringent quality standards of other demanding industries. Our ability to deliver quality products and ensure customer satisfaction is what drives our success.

Capabilities & expertise

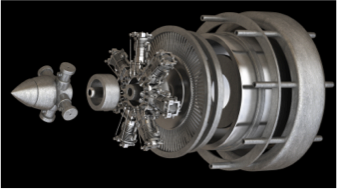

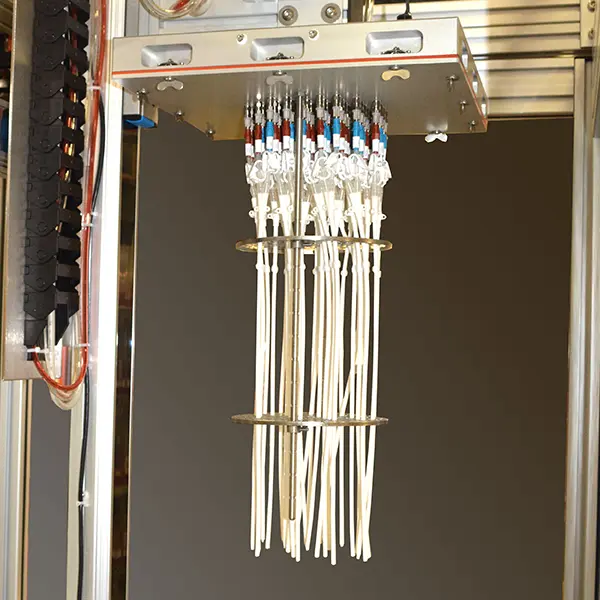

Simplify your supply chain with a single-source partner you can rely on for a full range of integrated, specialized manufacturing capabilities, including engineering, molding, extrusion, coatings, and assembly. We’ve built a network of cross-industry expertise that we apply across the critical markets we serve to create more value for our customers. With near-shore, off-shore, and low-cost manufacturing capabilities, our global network brings you convenience and flexibility to meet your manufacturing needs.

Comprehensive Capabilities

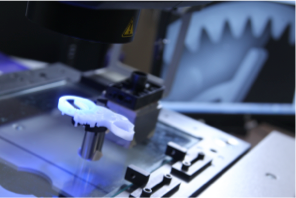

MOLDING

Coating & Automation

MANUFACTURING & ASSEMBLY

Serving

demanding markets.

MEDICAL DEVICES & LIFE SCIENCES

Industrial

AEROSPACE & DEFENSE

Energy

Helpful Tools

Startup leverages DFM, molding & complex assembly to delivery novel embolic catheter for 510(k) submission in only 4 months

Read case study

24/7 access to case studies, blog posts, capability briefs, and other useful information

Explore