ENGINEERING SMART SOLUTIONS FOR COMPLEX MANUFACTURING & ASSEMBLY.

Simplify your supply chain with a single-source partner you can rely on for a full range of integrated engineering and manufacturing solutions, including injection molding, blow molding, dip molding, extrusion, coatings, dipping and coating equipment, and assembly. With expertise ranging from design for manufacturing (DFM) to manufacturing to assembly, we support you as an extension of your team so that you can accelerate project timelines and bring high-quality products to market–faster.

EXPLORE OUR INTEGRATED

MANUFACTURING SOLUTIONS.

Navigate intricate engineering challenges effortlessly with Aptyx’s advanced engineering, precision molding, and manufacturing solutions. As your trusted partner, we provide a full suite of services for complex components and devices, from molding and extrusion to coatings and assembly. We’re committed to guiding your product to market success, with swift execution and results that endure.

Engineering

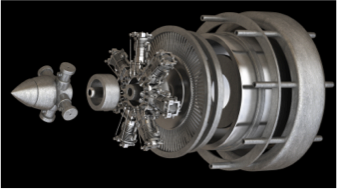

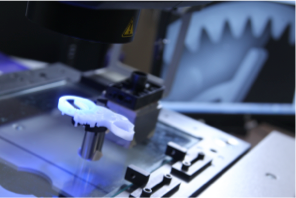

MOLDING

EXTRUSION

Coating & Automation

MANUFACTURING & ASSEMBLY

Where production meets partnership

COLLABORATIVE APPROACH

Choosing a manufacturing partner can be daunting. That’s why we take the time to listen and truly understand your needs to build the foundation of a trusting, long-lasting partnership. We believe in proactive, transparent communication, from onboarding to engineering and development and throughout production.

FLEXIBLE GLOBAL NETWORK

Our manufacturing facilities in the U.S., Canada, Mexico, and China offer specialized technologies and capabilities as well as ISO 13485 and ISO 9001 certifications. With domestic near-shore, off-shore, and low-cost manufacturing capabilities, we can meet the specialized needs of demanding industries.

TECHNOLOGY & INNOVATION

We have a 70-year history of developing innovative processes to bring customers’ ideas to life. With engineering at our core, we’re investing in our manufacturing facilities to ensure that we maintain the equipment, processes, and controls to optimize the production process.

QUALITY YOU CAN TRUST

We’re dedicated to delivering quality in every facet of our organization, from the manufacture of complex products to our interactions with our customers, suppliers, and team members. Our ability to provide quality products and ensure customer satisfaction is what drives our success.

Delivering for

demanding markets

Medical Devices & Life Sciences

Industrial

Aerospace & defense

Energy

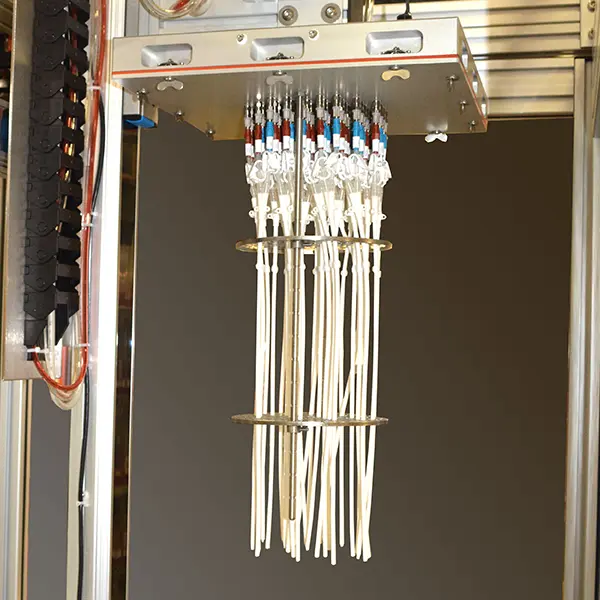

Startup leverages molding & complex assembly to deliver novel embolic catheter for 510(k) submission in only 6 months

Read Study

24/7 access to case studies, blog posts, capability briefs, and other useful information

Explore