Whitepapers, Webinars & eBooks

Stronger. Smoother. More Precise.

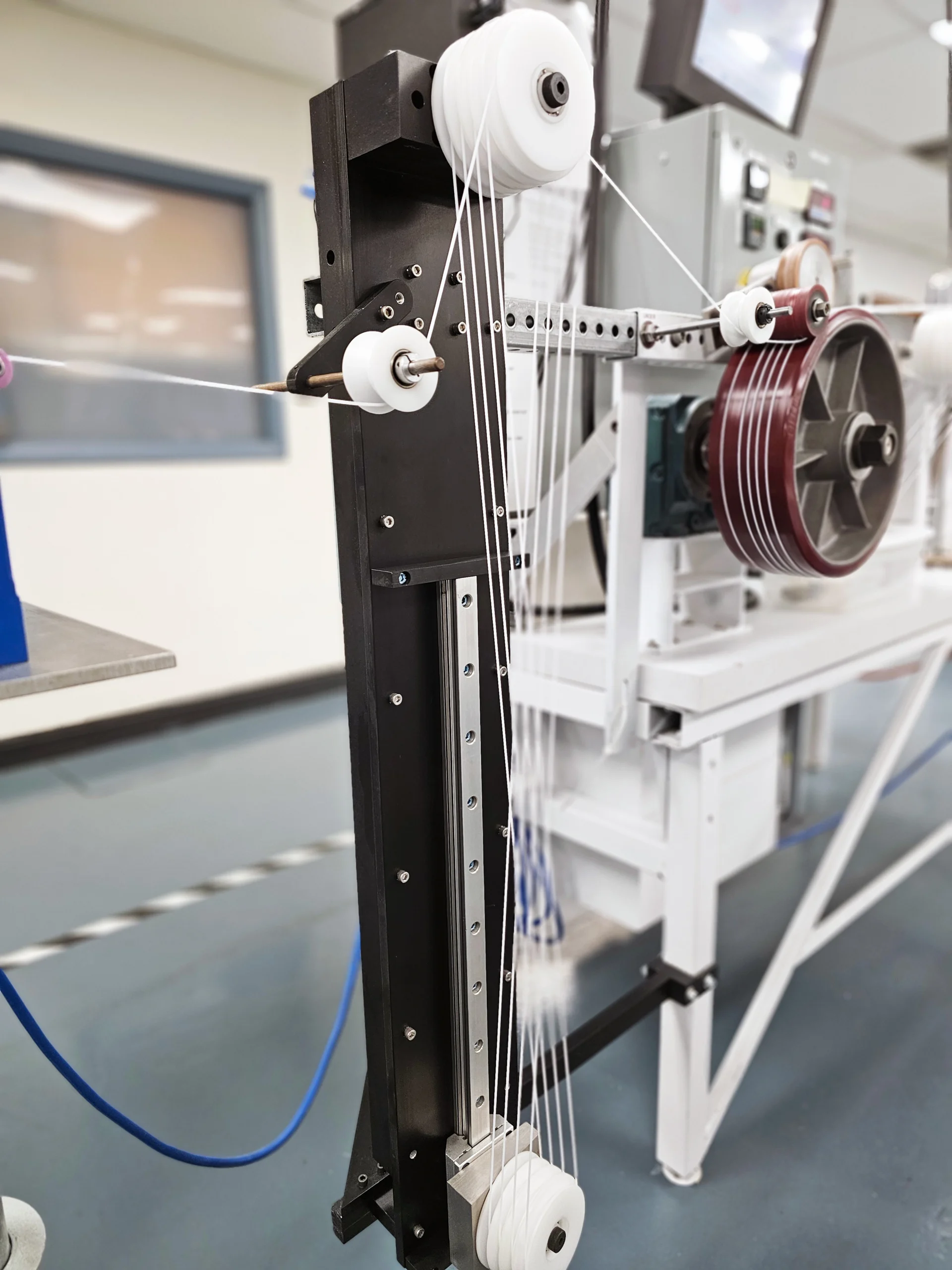

Aptyx core mandrel sets the standard in catheter manufacturing with proven performance that drives higher yields and lower risk.

When it comes to catheter and medical tubing manufacturing, precision and consistency aren’t optional—they’re everything. That’s why leading medtech companies trust Aptyx acetal core mandrel. We help you build better, faster, and with fewer risks by excelling in three critical areas:

-

- High Yields You Can Count On – Our proprietary surface finishes ensure smooth removal after extrusion or reflow, protecting lumen geometry and minimizing defects—so your yields stay high and your scrap rates stay low.

- Strength That Lasts Through Every Step – With tensile strength greater than 6000 psi / 32 lbs of force (lbf), Aptyx core mandrel holds up under heat, pressure, and high-speed production. That means fewer breaks, smoother runs, and more reliable builds.

- Unmatched Precision for Complex Devices – With outer diameter tolerances as tight as ±0.0003″ and ovality ≤0.001, our core mandrel gives you the dimensional accuracy needed for today’s most advanced neurovascular, structural heart, and multi-layer catheter systems.

From rapid prototyping to full-scale production, Aptyx brings the engineering expertise and scalable solutions to keep your innovations moving forward—without compromise.

Download the white paper to learn more.