Precision and Performance in Catheter Manufacturing: Unlock the Power of Acetal Core Mandrel

As medical devices become increasingly complex and miniaturized, the demand for precision-engineered components has never been greater. Join us for a fast, high-value webinar exploring how acetal core mandrel supports innovation and high yields in complex catheter and medical tubing manufacturing. The technology presented will demonstrate how advanced material science and process control can achieve exceptional dimensional accuracy, surface finish, and tensile strength — empowering you to innovate with confidence.

Whether you’re in R&D, manufacturing, or quality assurance, this session will provide actionable insights into optimizing your device builds with high-performance mandrel solutions.

Attend this webinar and learn:

- Material advantages of Acetal (polyoxymethylene) high-precision plastic versus other mandrel material choices

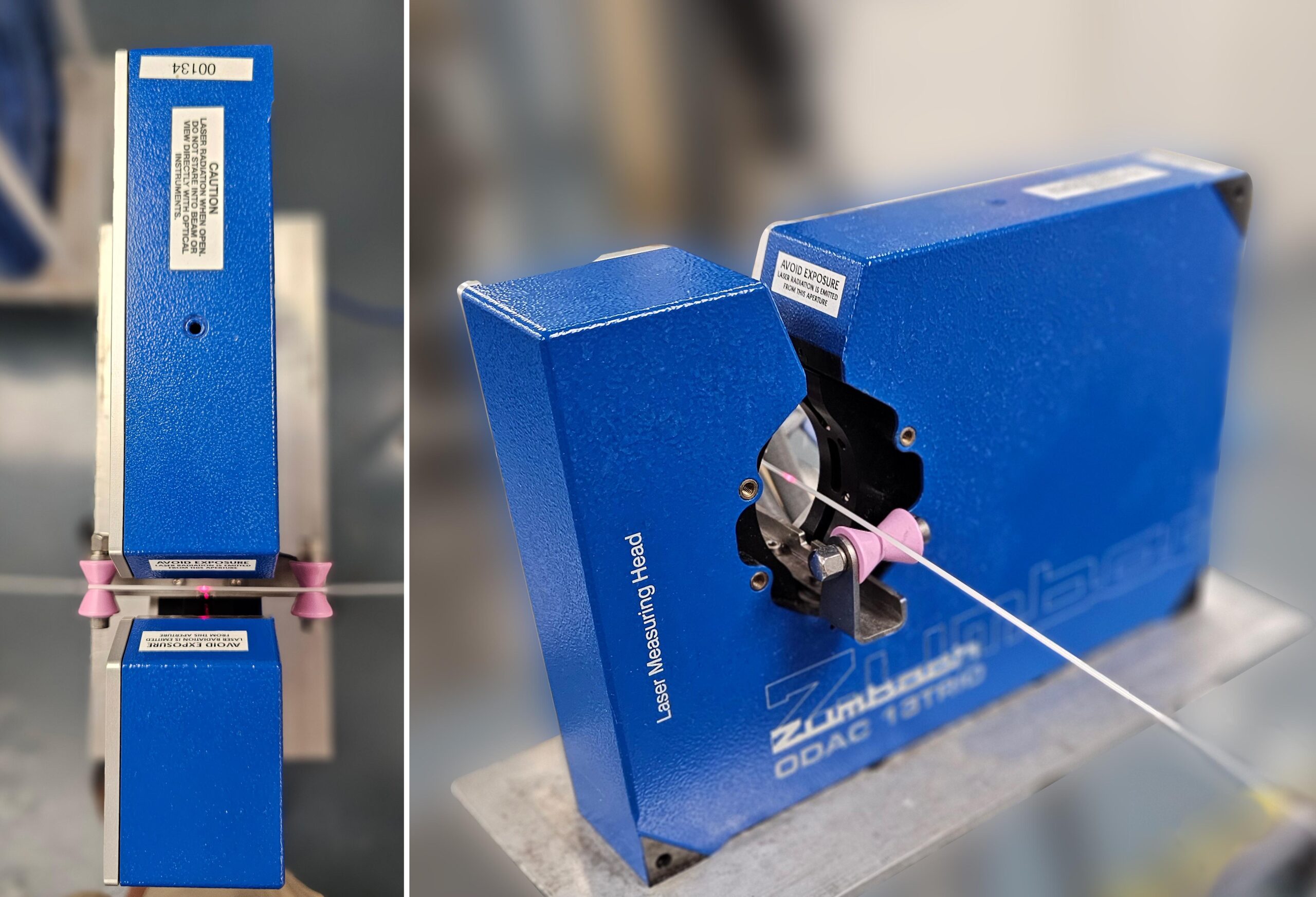

- How tight tolerances deliver high yields in complex catheter stackups

- The importance of surface finish in reducing lumen deformation and ensuring smooth release during extrusion and heat-shrink processes

- How high tensile strength supports demanding processing