Advanced blow molding technology,

customized for you.

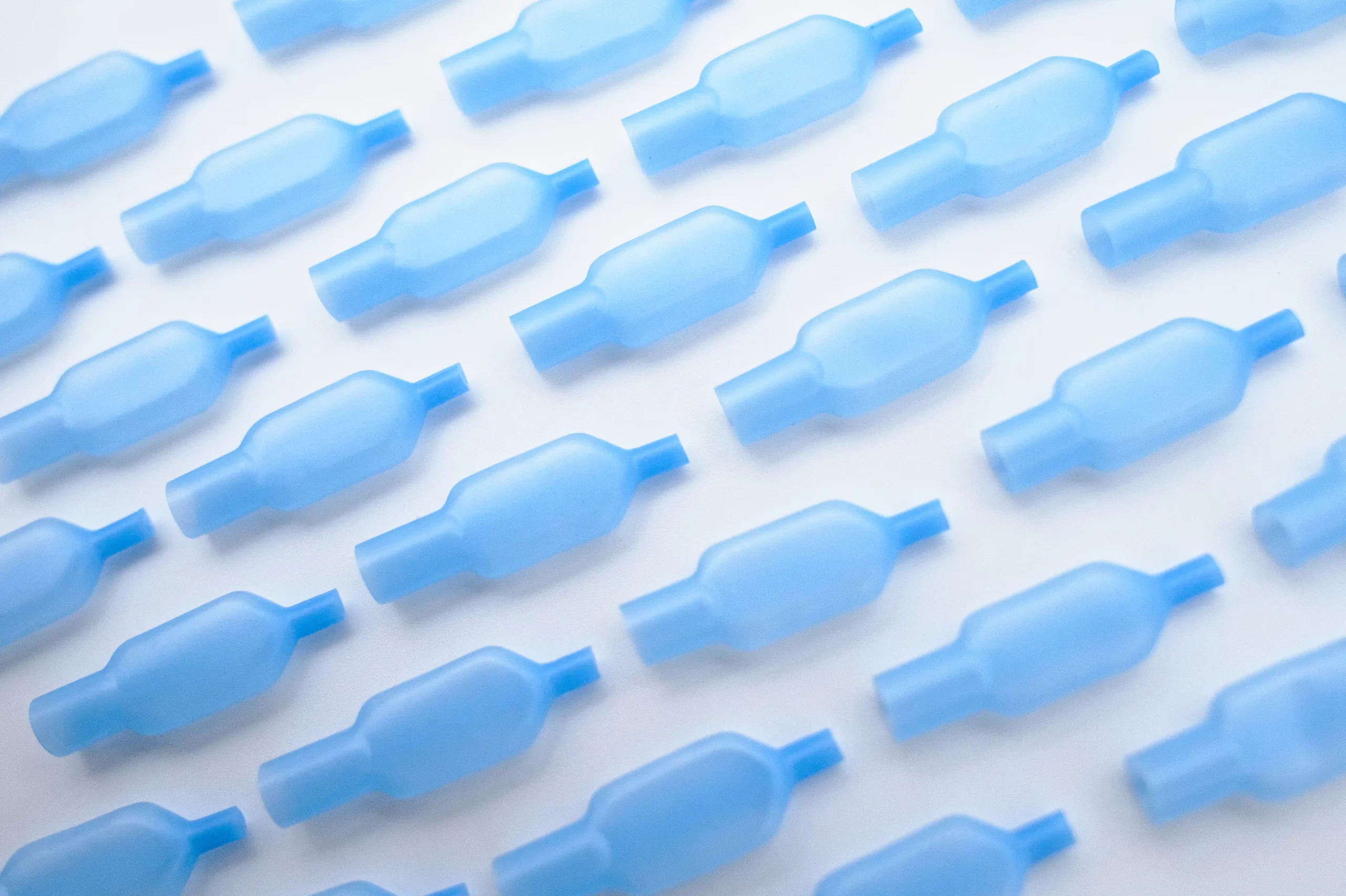

Expertise in medical balloons and other precision components

- Built for critical use – Ideal for thin-wall, durable, and hollow components used in medical, food-safe, and regulated applications.

- Flexible mold strategy – Choose from proven mold options or partner with us to create a custom mold that meets your specs.

- Expertise in complex profiles – Our skilled craftspeople specialize in advanced blow molding, including balloon components with demanding geometries.

Blow molding solutions you can count on.

Aptyx provides versatile blow molding services for the medical device industry and other high-performance markets. Whether you need high-volume 4+4 continuous extrusion blow molding or micro medical blow molding for complex components like medical balloons and cuffs, we have the capabilities to bring your product ideas to reality.

Combining control and cost-effectiveness.

Polymer custom blow molding allows you to produce a hollow complex part design at scale. This process uses compressed air to meld down a specialized polymer tube (called a parison) to create a uniform shape and thickness around the walls of a metal mold. The OD can be controlled via a steel or aluminum mold and the ID via compressed air.

Blow Molded Products

Medical balloons & cuffs

We blow mold medical balloons and cuffs for a wide range of applications including endotracheal, stent delivery, tracheostomy, endoscopy, gynecology, and urology applications. Our team has decades of experience producing thin-walled cuffs that are durable yet supple with a limited transition from the balloon shoulder to the tube. We can provide you with blow-molded components with walls as thin as .0015” and with shoulder IDs as small as .075”.

Food safety applications

We manufacture blow-molded handles for the food and beverage industry that meet stringent quality and industrial safety standards.

Polymer Blow Molding Advantages

Efficient high-volume production

Once the mold or die has been fabricated, the blow molding process can quickly and reliably produce parts, making it a good choice for medium and high-volume production of the same hollow part.

Control of wall thickness & complex designs

Compared with dip molding, custom blow molding allows for improved control of wall thickness, along with more advanced, complex mold designs.

Cost-effective production process

Extrusion blow molding uses a lower level of pressure, which reduces machinery costs. This makes it easier and more cost-efficient to mold external threads or open-ended and large parts, which can be split by opening a closed molding. This blow molding solutions technology also reduces labor cost.

Airway management and respiratory delivery: Because every breath matters.

Read brief

Resources

24/7 access to case studies, blog posts, capability briefs, and other useful information

Explore