Expertise spanning injection molding, dip molding & blow molding.

- Deep materials expertise – Our team leads the industry in plastic injection molding, dip molding & blow molding for even the most demanding applications.

- Process selection support – We advise on the right molding approach based on your product design, performance requirements, and budgetary goals.

- From prototype to production – With full in-house capabilities, we take your component from early development through scalable manufacturing.

Your molding challenges.

Our solutions.

Make Aptyx your strategic partner for all your complex molding needs. Our team of experts has unmatched depth and breadth of experience in custom precision molding processes, supported by engineering design and tooling expertise. With diverse material capabilities, we can also help you to choose the optimal material for your project.

Plastic Injection Molding

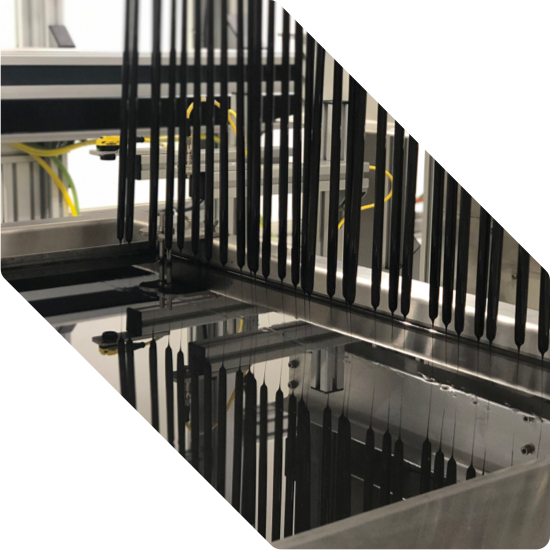

Dip Molding

Blow Molding Solutions

Design Support

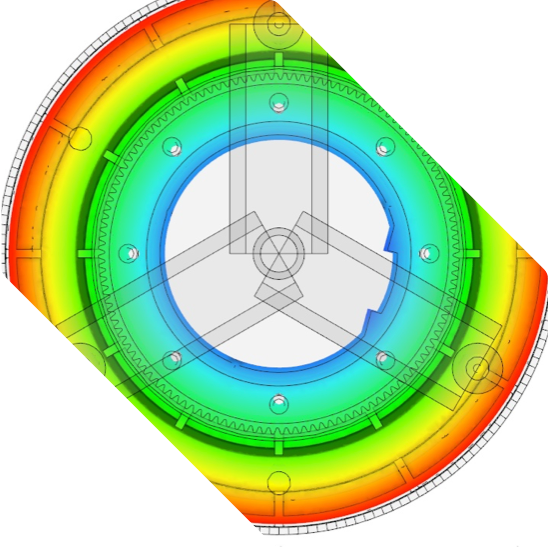

Tool design & Build

Custom Molded Products

INTRAVENOUS INFUSION PUMP SYSTEM

Aptyx optimized the design for scalable manufacturing and supplies the mission-critical gear system that precisely drives the pump module and several support components and sub-assemblies within this product.

ROBOTIC SURGERY SYSTEMS

From the reusable control arms to the disposable end of arm devices, Aptyx assists in the design and tool build and produces the mechanical drive system for many of the leading robotic surgery systems.

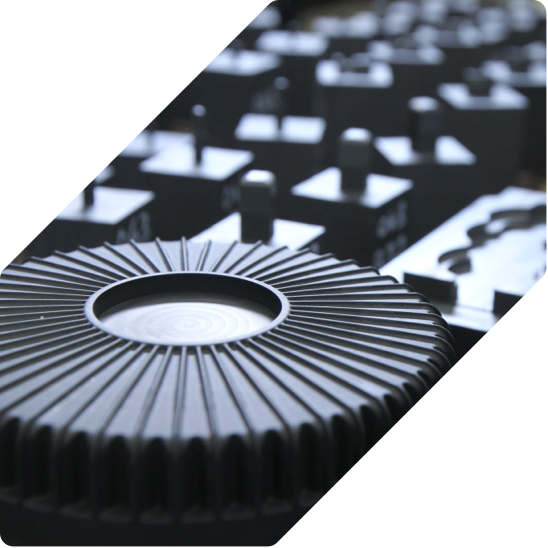

PLASTIC GEARS

High-strength plastic gears are key to the precise functioning of various equipment used in the medical device, industrial, aerospace and defense, and energy industries. Examples include medical fluid delivery pumps, automated teller machines (ATMs), and vehicle and building HVAC equipment.

NASAL CANNULAE

Dip molding allows us to create complex geometries in a single component.

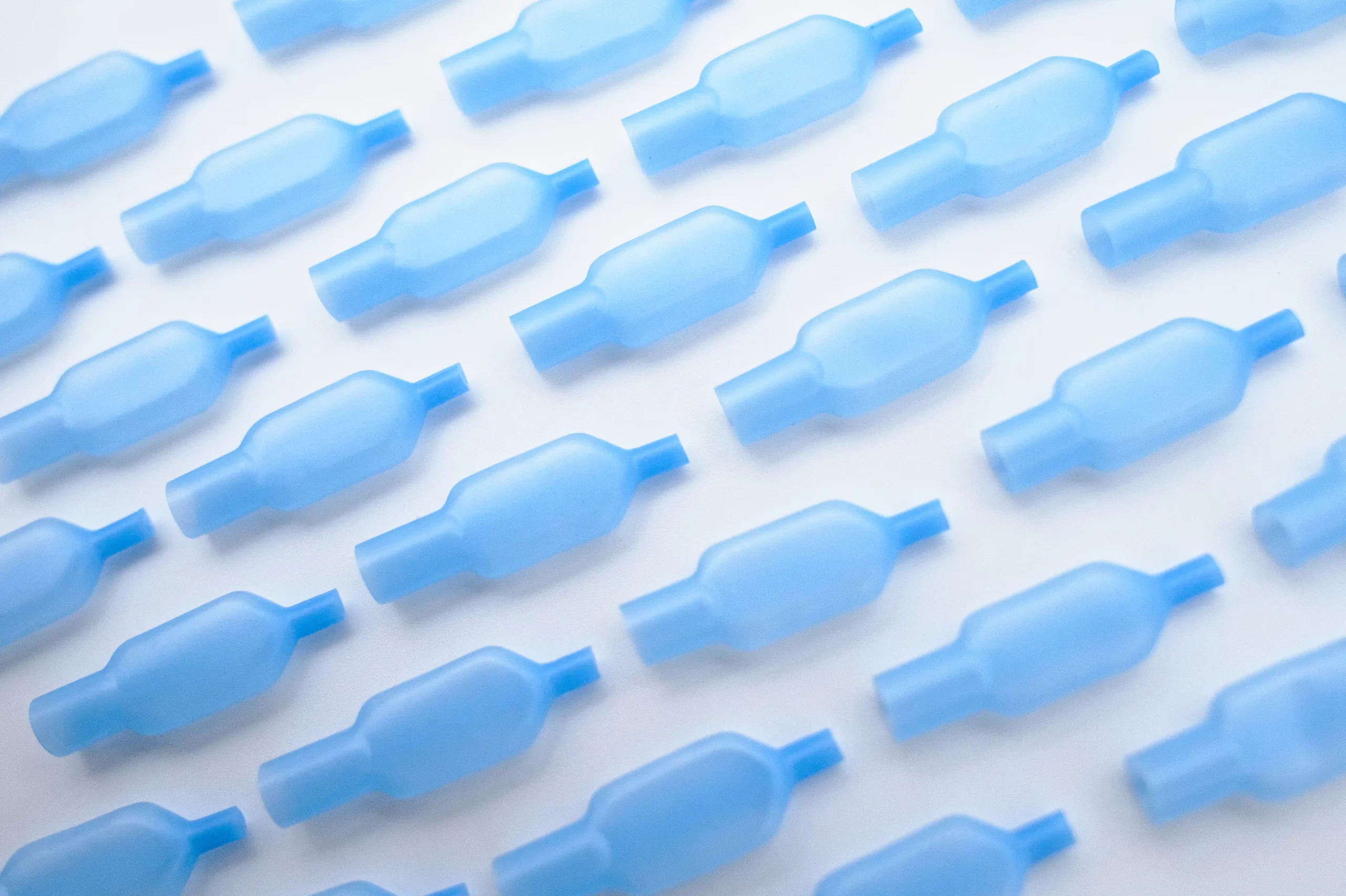

MEDICAL BALLOONS & CUFFS

We dip and blow mold medical balloons and cuffs for a wide range of applications including stent delivery, endoscopy, and urology applications.

Meeting the challenges

of critical markets.

Medical Devices & Life Sciences

Industrial

Aerospace & defense

Energy

Helpful Resources

Materials, molding, and complex precision gear expertise dramatically reduce cost and improve quality of components for robotic surgery system

Read Study

24/7 access to case studies, blog posts, capability briefs, and other useful information

Explore