Interventional systems that shape

what’s possible tomorrow.

Comprehensive solutions From concept to commercialization.

- End-to-end solutions – We provide comprehensive support and seamless collaboration, from D&D to volume manufacturing of components and devices.

- Strict cleanroom standards – Our expanded ISO Class 7 cleanroom footprint ensures the highest standards in quality, consistency, and regulatory compliance.

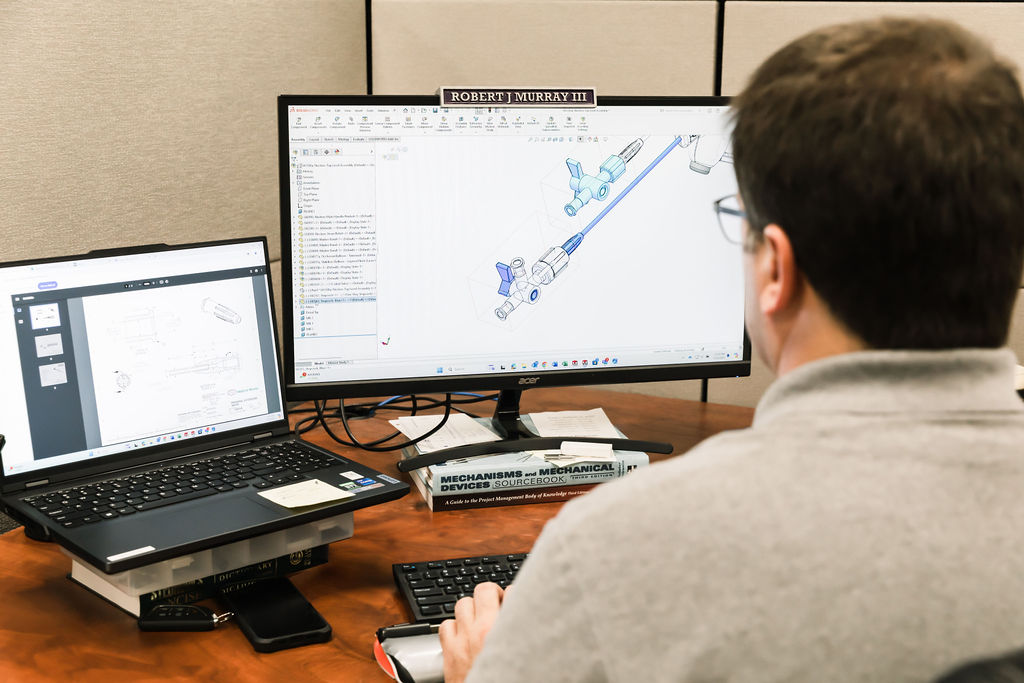

- Engineering excellence – With a deep bench of talent and specialized development engineers, we bring unmatched expertise in interventional and transcatheter devices.

Development

From design and rapid medical device prototyping to validation testing and pilot production, we ensure your designs are optimized for performance, manufacturability and scalability.

Testing

Our accredited ISO/IEC 17025:2017 laboratory ensures your interventional products, materials, and packaging meet stringent industry standards before they reach the market.

Manufacturing

We offer a broad range of advanced manufacturing and medical device assembly capabilities, custom equipment, and highly skilled operators to help you navigate the entire medical manufacturing journey.

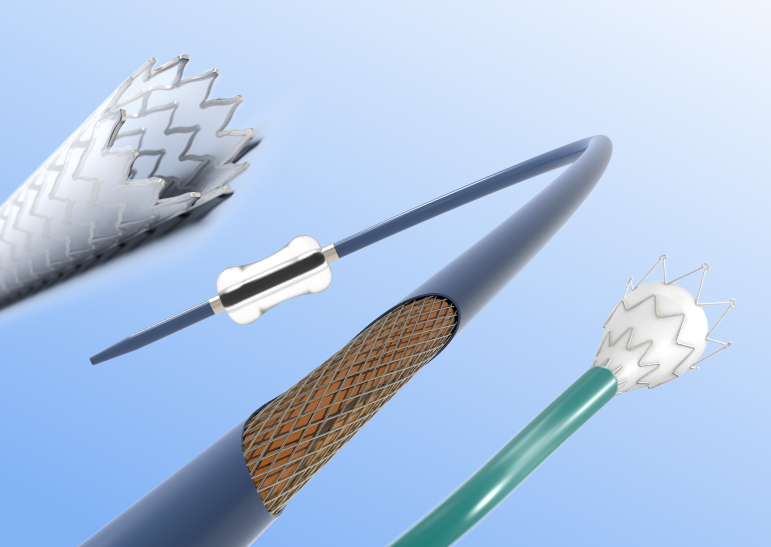

When you need world-class design, development, and manufacturing for cutting-edge implantable medical devices, Aptyx delivers. With ISO Class 7 cleanroom manufacturing, a deep engineering talent pool, and expertise in high-performance materials, we bring the quality and reliability required for complex applications – from stent grafts to valve repair, regenerative scaffolds to ureteral stents, gastric balloons to implant delivery systems, and more.

Our implantable solutions are wide-ranging and designed to meet the highest standards:

- Covered Stents & Frames

- Stents

- Structural Heart

- Medical Textiles

- Bioabsorbables

At Aptyx, complex catheters are second nature. With over 25 years of expertise, our dedicated engineering teams have worked closely with customers to deliver the highest quality solutions, from catheter prototypes to full-scale manufacturing. Our approach? Deep collaboration, smart engineering, and manufacturing precision – all designed to help you bring innovative catheter-based solutions to life with confidence.

Whether for vascular, gastrointestinal, urologic, or other interventional markets, we’ve got you covered:

- Stent Delivery

- Stent Graft Delivery

- Balloon Catheters

- Steerable & Deflectable

- Sensor Integration

Aortic

Structural Heart

Peripheral Vascular

Neurovascular

Gastroenterology

Urology

MATCHING MATERIALS TO APPLICATIONS FOR OPTIMAL RESULTS.

Behind every high-performing medical implant is the right material – carefully selected for its biocompatibility, durability, and functional performance. At Aptyx, we don’t just supply materials; we help you engineer confidence into every device.

Our experts take a full-lifecycle approach to material selection, ensuring your components stand up to the demands of manufacturing, performance, and patient safety. Whether you need flexibility, strength, or bioabsorbability, our diverse material portfolio is designed to match the right properties to your device’s unique requirements.

Explore our advanced material solutions:

- ePTFE

- Polyester

- Nitinol

- Polyurethane

- Silicone

- Bioabsorbable Polymers