Don't know where to start

with dip coating or molding?

We'll guide you through the process with unmatched expertise.

- Expert technical support – Our team helps you evaluate coating options, tooling design, equipment needs, and long-term production strategy.

- In-house lab services – We provide product and process development, plus small-scale runs for testing or market evaluation.

- Seamless path to scale – We work with you from early-stage development through commercialization to ensure your design is scalable and production-ready.

Drawing from our extensive expertise, our team can assist in the development of a wide range of dip molding and dip coating products, from concept to testing. We are here to help you with:

- Material recommendations in partnership with coating solution providers

- Customized process parameters to create in-house samples

- Ability to scale manufacturing and reduce costs

Prototype development is a critical stage for any new product. We use our in-house laboratory to produce, evaluate, and refine working prototypes, so you can go from idea to testing quickly and cost-effectively. Ways we can work together include:

- Refining coating type and process requirements

- Prototyping using multiple coatings to evaluate in parallel

- Producing true operational prototypes for testing and marketing studies

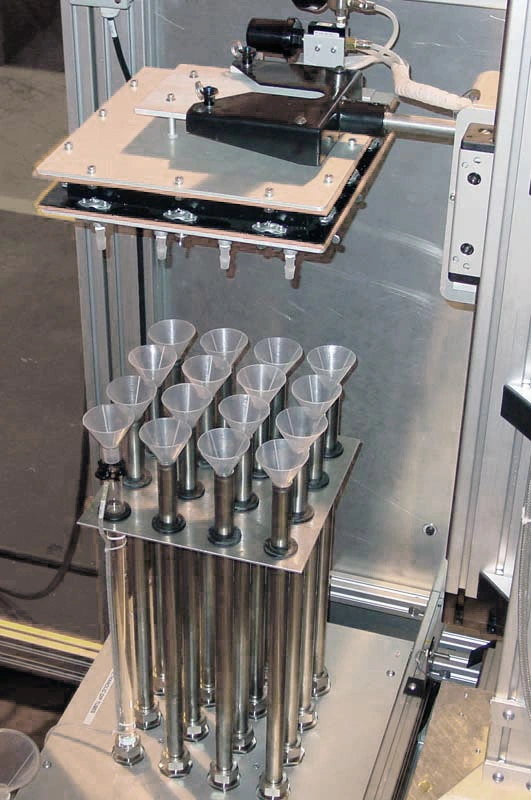

Our engineers have extensive experience in tooling and mold design. Using customer input on the final product features, we can assist in the development of necessary molds and incorporate any customizations you require. Ways we can work together include:

- Incorporating various quick disconnect methods to enable rapid changeover

- Mold material selection to achieve desired characteristics

- Finish selection for wall thickness uniformity, desired texture and clarity

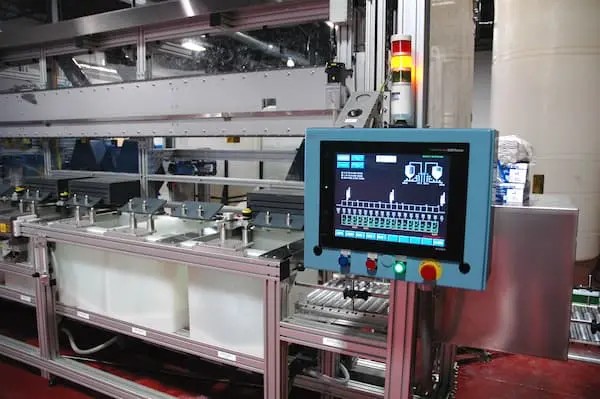

Defining and refining process parameters is essential to the success of producing dip molded or dip coated products. With our in-house laboratory, we tailor your processes so you can achieve your desired product characteristics, every time. Our team helps:

- Customize required process steps to achieve desired product characteristics

- Define acceptable tolerances and critical controls by process simulations

- Provide accurate estimates for budgetary review of equipment and product costs

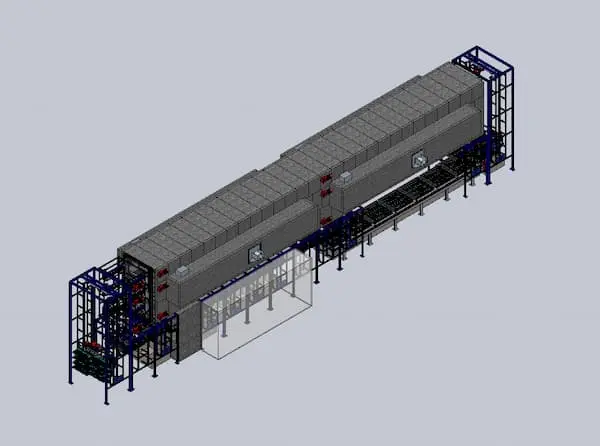

Development equipment is often the crucial means to ensure accurate process definition. It is instrumental in the production of test and marketing samples, as well as the evaluation of multiple coating solutions. To achieve the best results, we provide:

- Turnkey Diplomat® series for pilot and small scale production

- Customized equipment to meet virtually any project parameter

- Support from R&D and prototype stage to high volume production