One source.

More extrusion solutions.

LEARN ABOUT OUR NEWLY EXPANDED CAPABILITIES

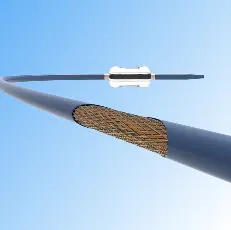

- Boston-strong, ready now – Located in the heart of Boston’s medtech corridor, we bring immediate capacity to fuel device innovation close to home.

- Custom capabilities, specialized expertise – From in-house tooling to precision performance, our seasoned team dives deep into every detail.

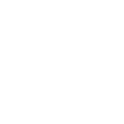

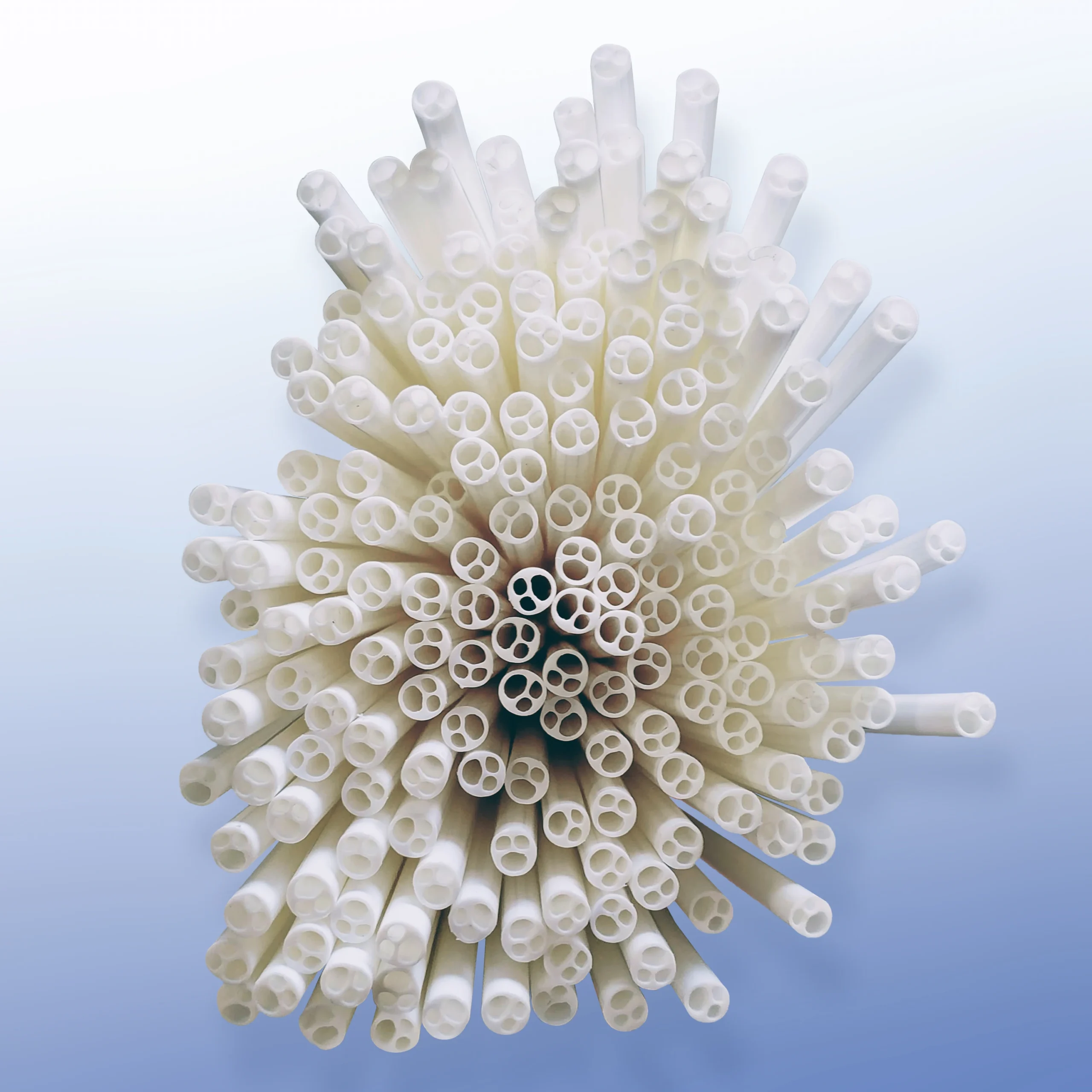

EXPANDED PRECISION EXTRUSION CAPABILITIES

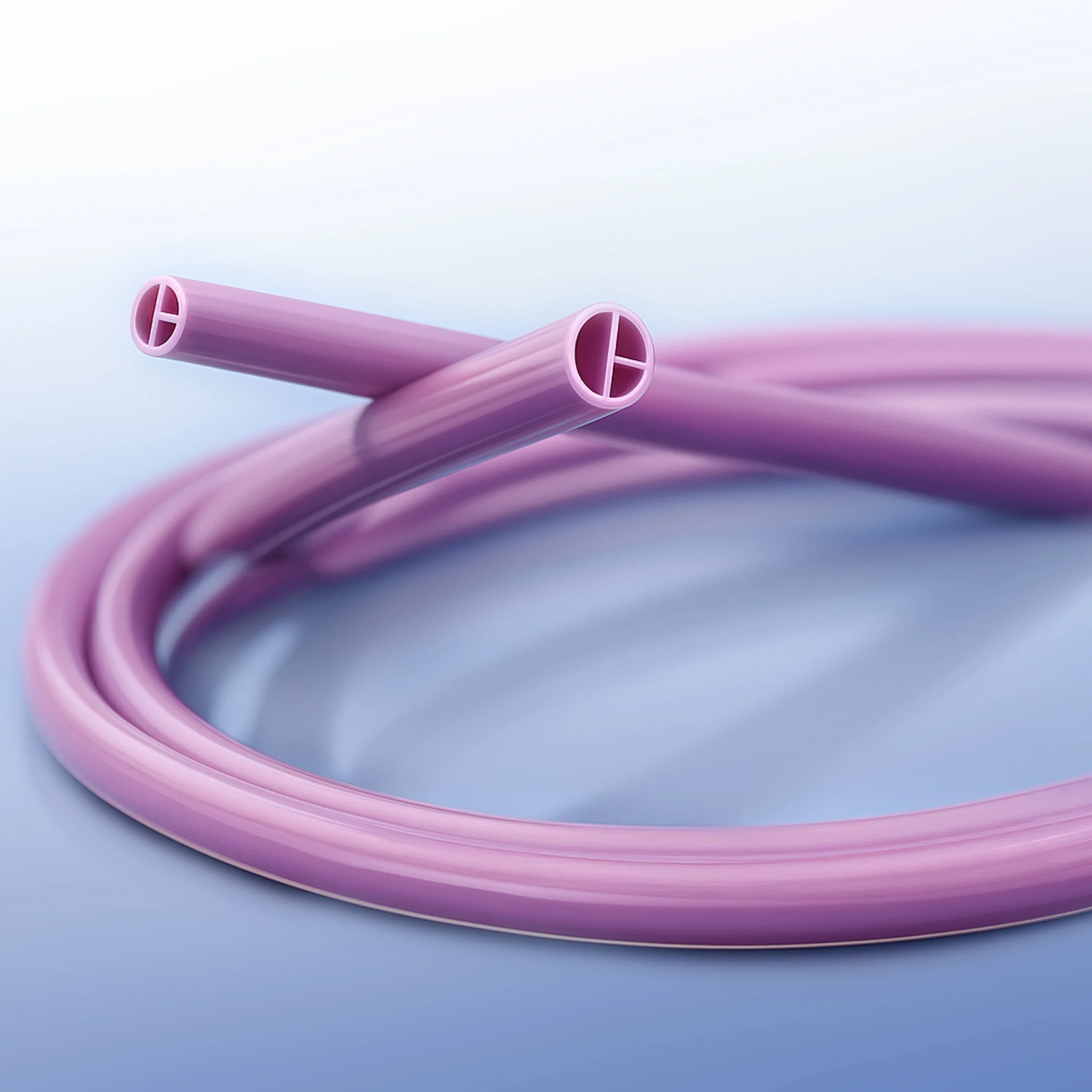

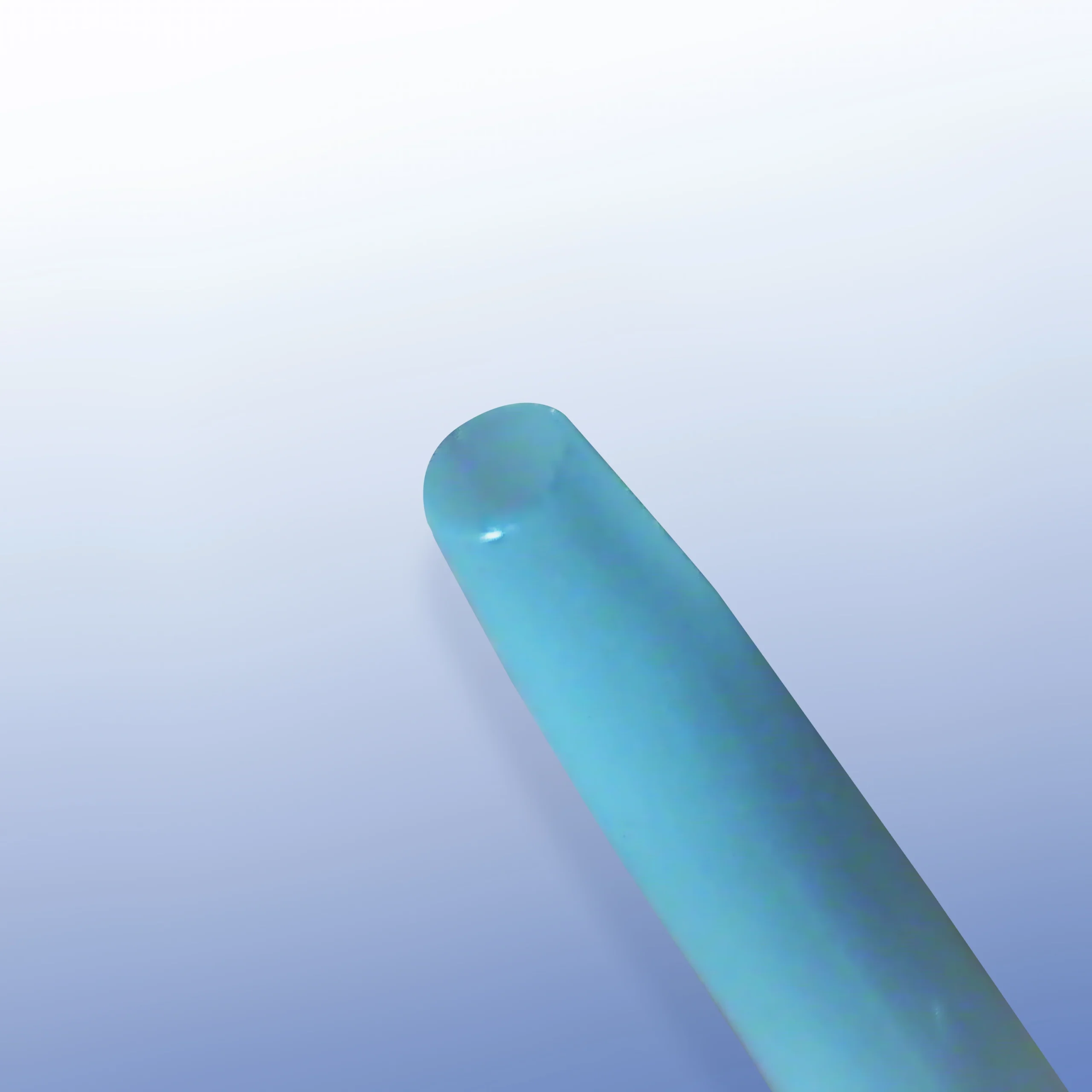

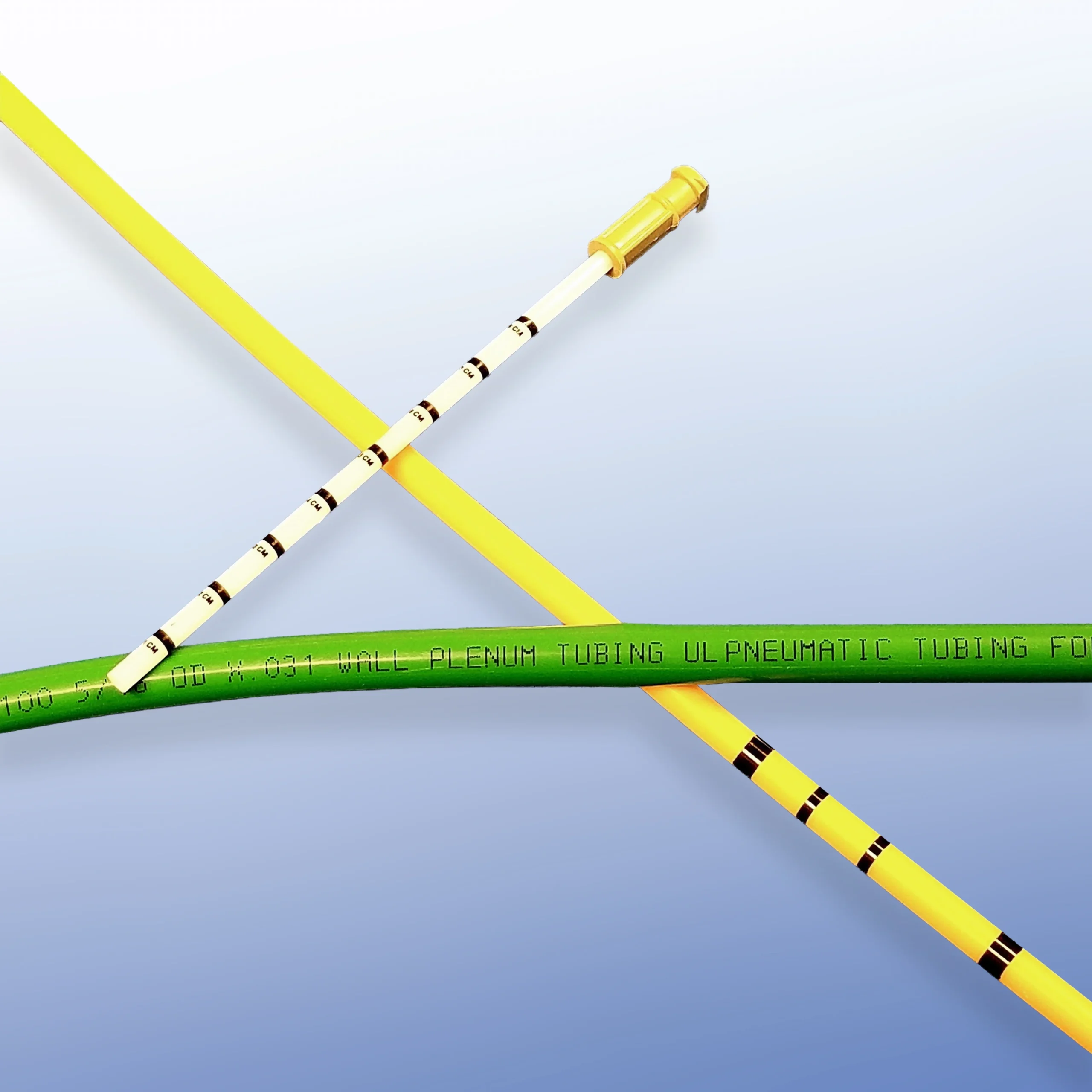

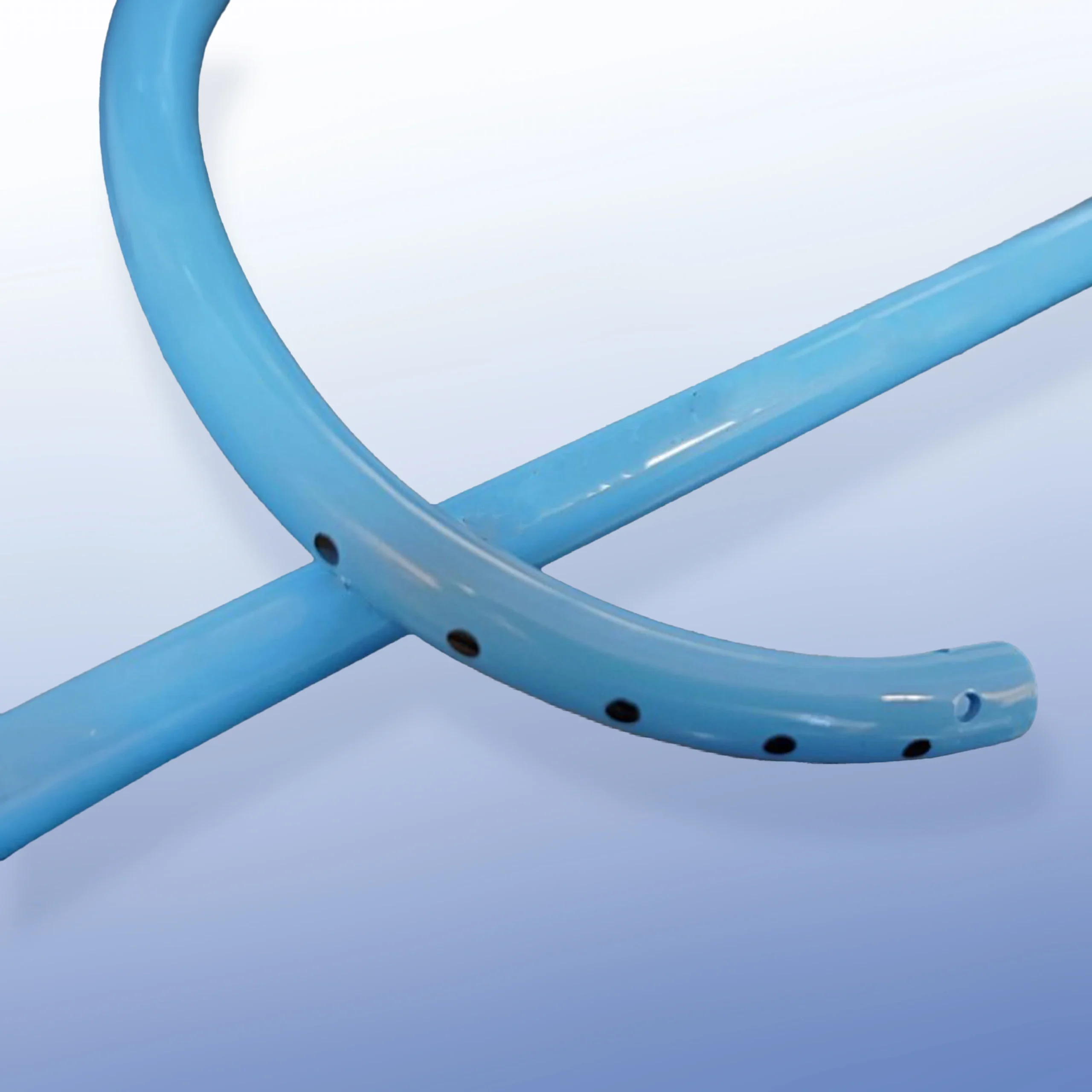

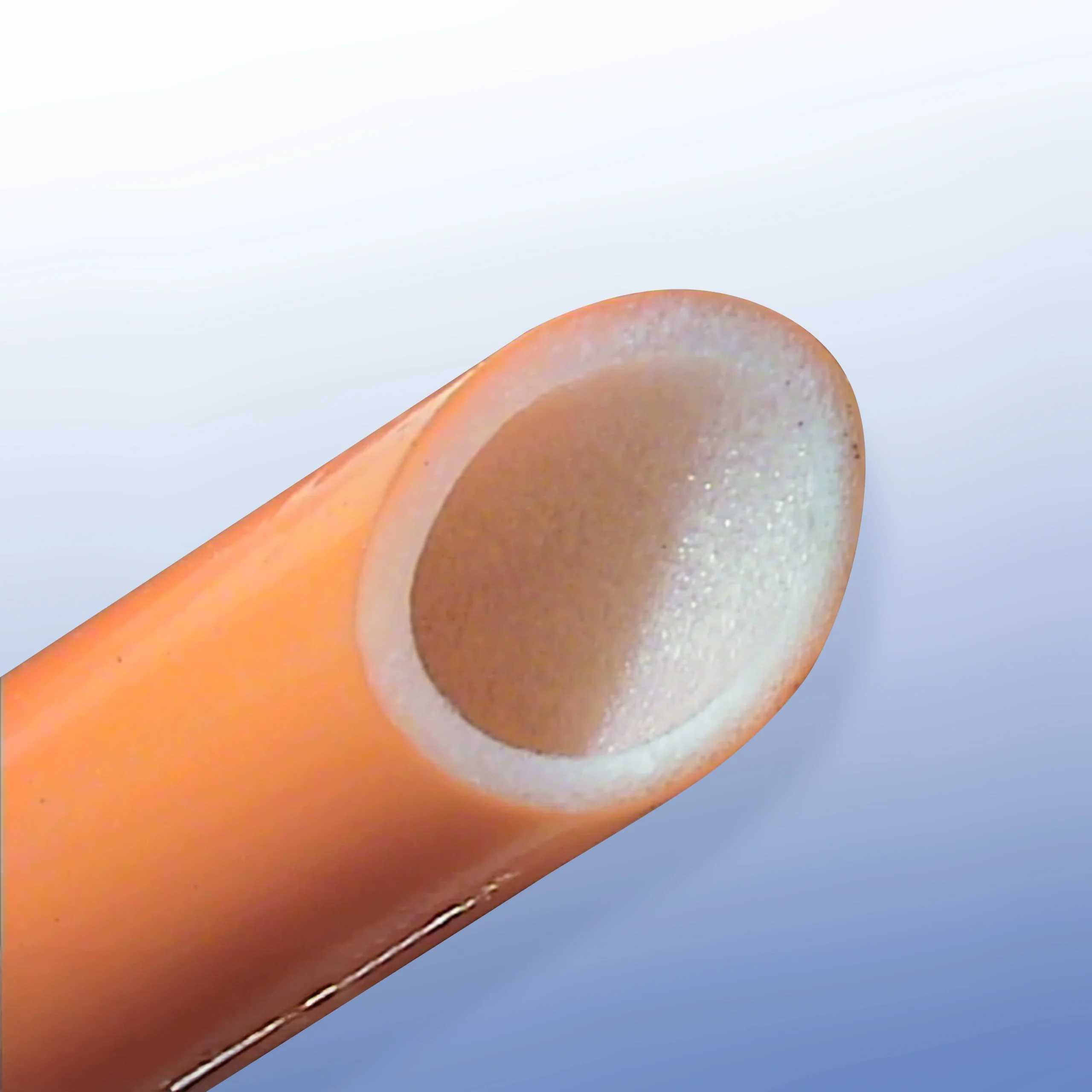

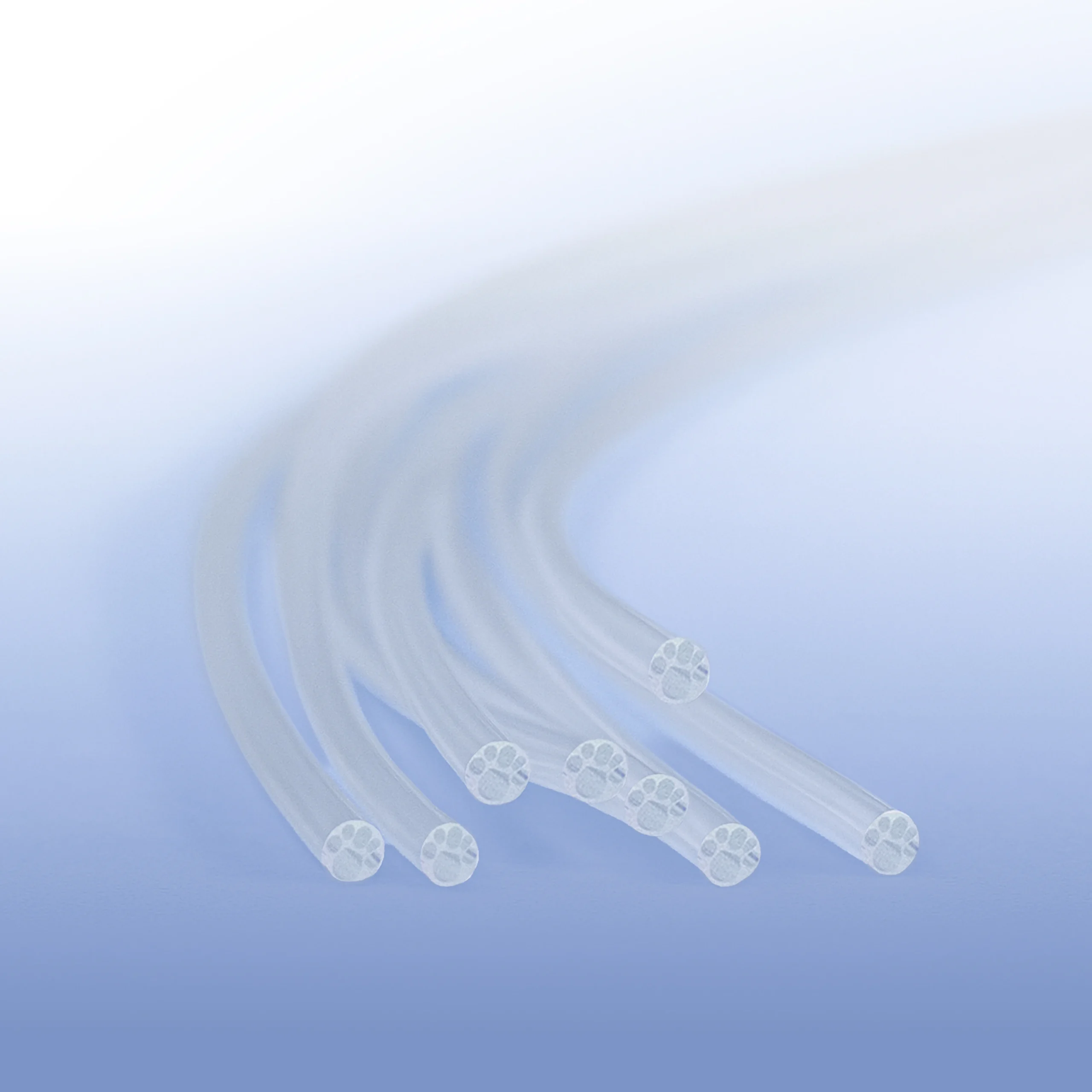

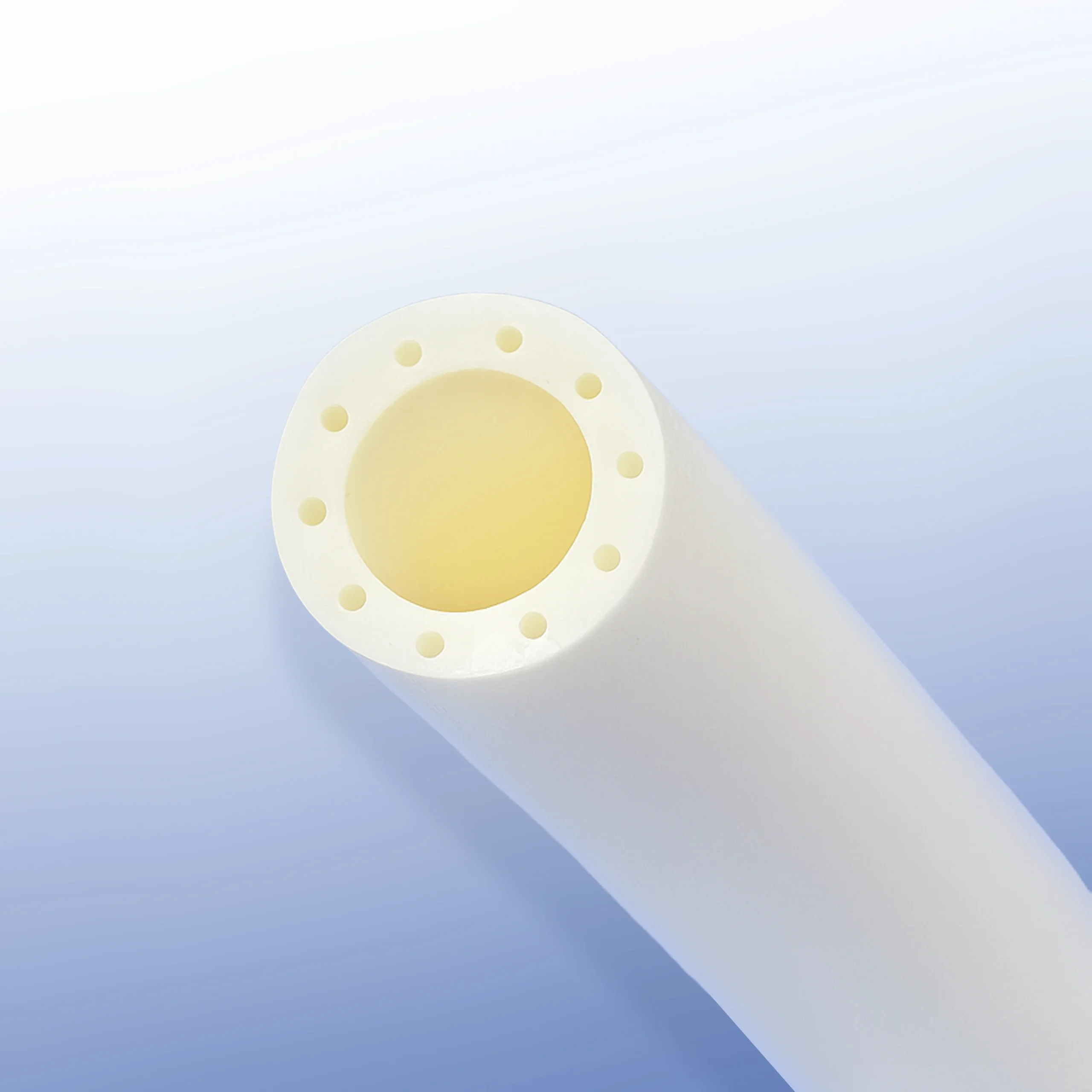

Our expanded capabilities deliver catheter-grade performance, with ultra-tight ID/OD tolerances, wall thickness from .001”, and reliable lumen integrity.

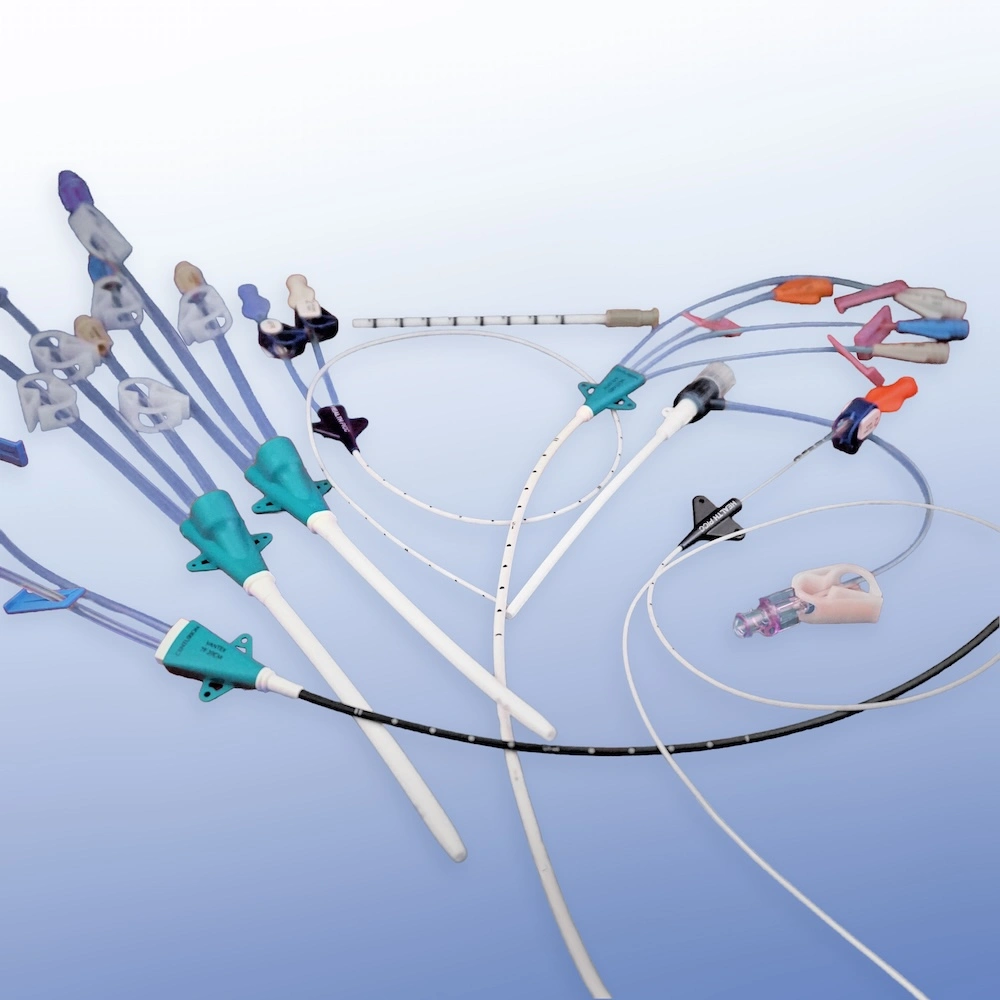

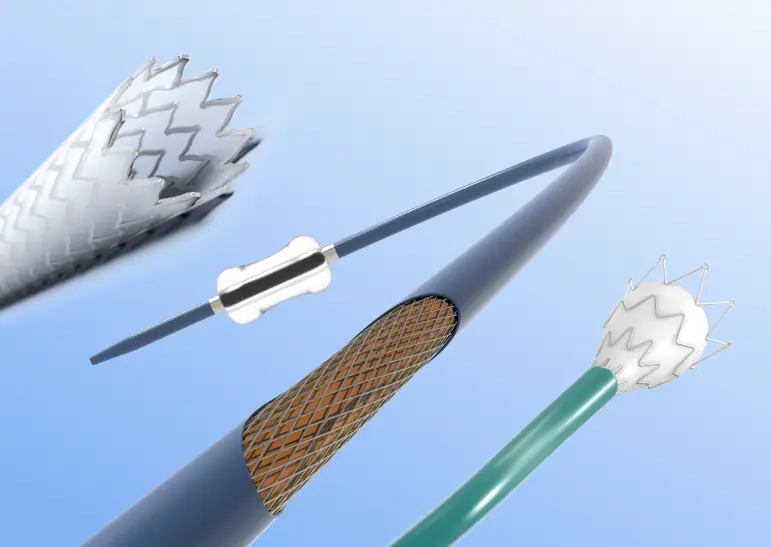

DEEPER VERTICAL INTEGRATION & EXPERTISE

Complex devices have even more support from Aptyx’s full suite of end-to-end solutions, including D&D and engineering, molding, coating and assembly.

QUICK TURN PROTOTYPING & PRODUCTION

In-house tooling design drives quality and speed, allowing for quick turn manufacturing in a clean environment.

- Multi-lumen

- Specialty profiles

- Precise taper tubing

- Micro extrusions

- Co-extrusion

- Multi-layered extrusion

- Balloon tubing

- Wall thickness from 0.001”

- Diameters .007” to .75”

- ID/OD tolerances to 0.0005″

- Custom cut to length solutions

- Durometers below 25A

- Forming

- Tipping

- Flaring

- Closures

- 360° scoring

- Bevels and edge breaks

- Capillary tubes

- Printing

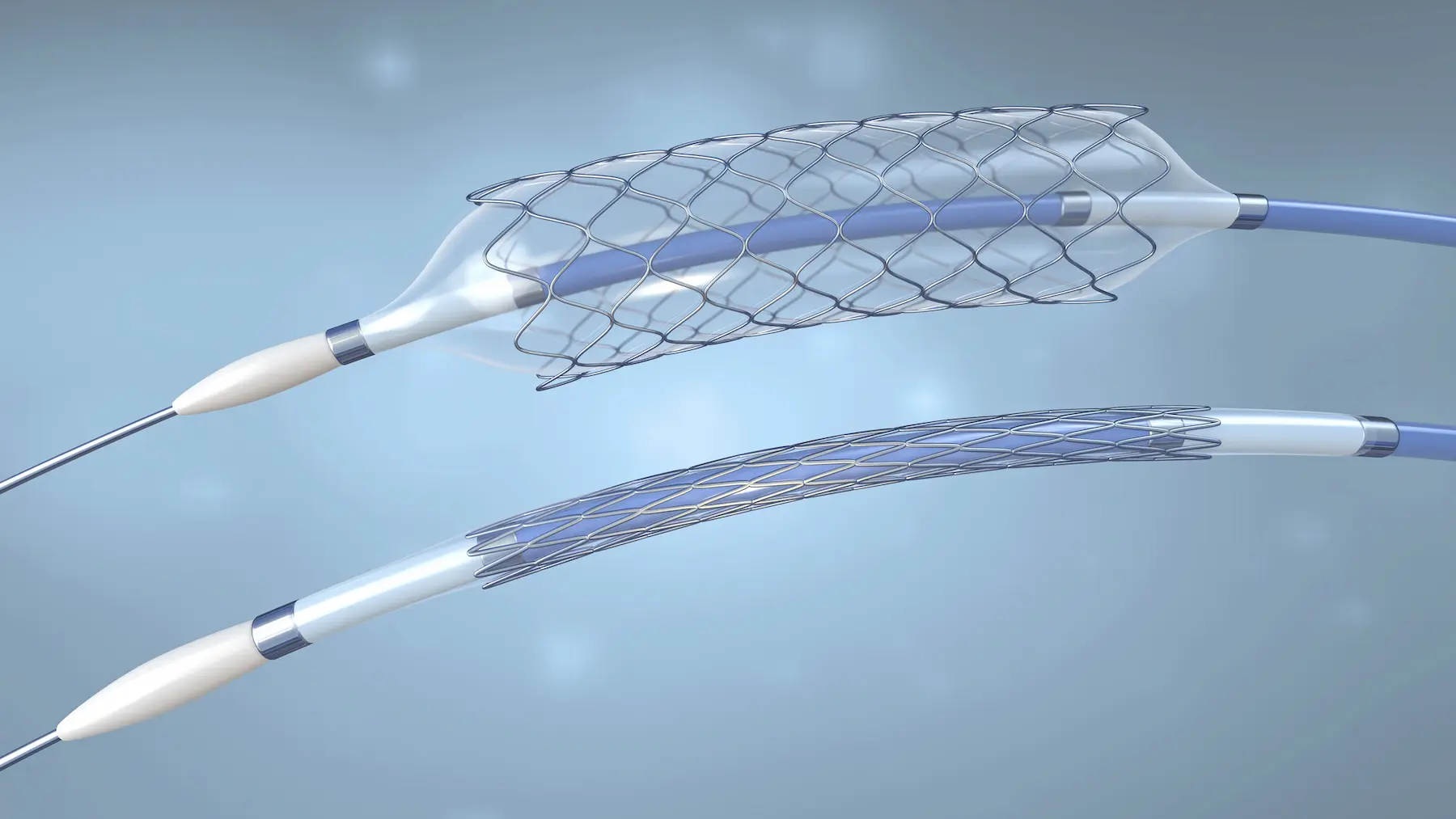

- Braiding and coiling

- Overmolding

- Assembly

- Transparent radiopaque materials

- Polyolefins

- Thermoplastic polyurethane (TPU)

- Thermoplastic elastomer (TPE)

- Nylons

- Polyether block amide (Pebax®)

- Polyetheretherketone (PEEK)

- Fluoropolymers (FEP)

- Polyvinyl chloride (PVC)

- Low friction additives (PTFE alternative)

- Inherent antithrombotic additives

Talk with an Aptyx expert to explore

even more product applications.

With over 25 years of experience delivering catheter and implant innovation, Aptyx is your interventional manufacturing partner across catheter and implant development, testing and manufacturing.

Learn more

Our seasoned team designs tooling in-house, so you get tighter tolerances, faster speeds, and less risk across the entire production process.

- Proprietary tooling to extrude complex plastic tubing

- Quick turnarounds for sample product as well as production

Quality starts at the line and runs through every lot – our expertise, controlled environment and proprietary DI/RO water system ensure rigor you can rely on.

- Extrusion lines in a controlled environment

- Proprietary water system with filtered DI water and bioburden controls

- Controlled loop with SPC feedback, multi-axis laser gauges and ultrasonic measurement systems

Discover how Aptyx’s interventional capabilities and expertise can help you.

Download PDF

24/7 access to case studies, blog posts, capability briefs, and other useful information

Explore