Reach out anytime – Aptyx experts are always in.

When you partner with Aptyx, you’re not just getting capabilities—you’re getting the brilliant minds behind them. From molding to extrusion and beyond, our experts are here to help turn your toughest challenges into success stories.

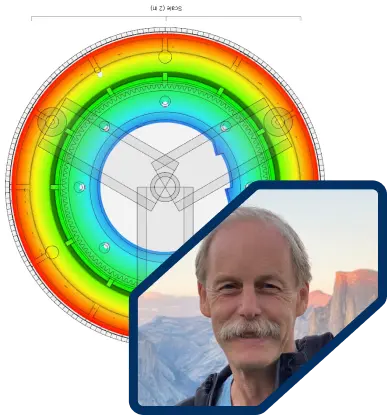

At Aptyx, engineering precision is more than a promise—it’s a partnership. Leading the charge is Ray “Raydini” Scherer, our predictive engineering wizard. With more than 30 years of expertise in DFM, tooling and molding, he helps customers avoid costly missteps and optimize their designs for success. From the first spark of an idea to full-scale production, Ray ensures every part exceeds expectations—because we’re not just building components; we’re building confidence.

One of the foundations of exceptional manufacturing is advanced tooling – and no one knows that better than Jarrod Aydelott. With nearly two decades of hands-on experience, Jarrod has mastered the art of design-for-manufacturing, simulation, complex tooling systems, and molding cell development. His ability to blend technical skill with a customer-first approach ensures that even the most challenging designs become manufacturable realities.

Turning complex challenges into scalable success is what we do best at Aptyx. Jeff Charlton has spent more 35+ years in high-performance dip molding, coating and automation systems. Since founding DipTech Systems, now part of Aptyx, Jeff has been involved in more than projects, including 40 high-volume automation systems. His ingenuity ensures our customers achieve precision, scalability, and success at every step.

Extrusion is where precision meets possibility – and Patrick Daly proves it with every project. With over 20 years in the medical device industry, he specializes in extrusion engineering and polymer processing, tackling everything from single- and multi-lumen tubing to complex co-extrusion processes. His deep materials expertise and hands-on approach ensure your components meet the highest standards, whether for prototypes or high-volume production. He also plays a mean guitar.

With the acquisition of Medical Murray’s

Charlotte, NC facility, we welcome:

Turning ideas into life-saving solutions is Eric Leopold’s zone of genius. As Chief Technology Officer at Medical Murray, Eric led the company’s technology and strategic objectives while also supporting the research and development of new complex catheters and transcatheter implants. With 25+ years of medical device experience in endovascular and minimally invasive devices and 30 U.S. patents to his name, Eric’s leadership ensures groundbreaking technologies deliver real-world impact.

Interventional product development can be extremely complex – and having a seasoned partner can make all the difference. Chris Steadham brings more than 25 years of international cross-functional leadership in Research and Development, Operations, and General Management of Class II and Class III products. With a background that spans engineering, manufacturing and sales, his track record of success extends from new product development through commercialization, and beyond.