Customer Situation

A large global ventilator supplier was looking to develop a heated breathing circuit that could be used for humidified ventilation without the use of water traps that require regular draining. The customer faced two challenges. First, existing products on the market were protected as intellectual property. Second, the customer was concerned about the safety of a circuit that contained electrical wires within the hose construction.

The customer was already working with Aptyx on another tubing product and was familiar with the R&D team, the depth of its skillset, and its proven ability to provide creative solutions.

Aptyx Solution

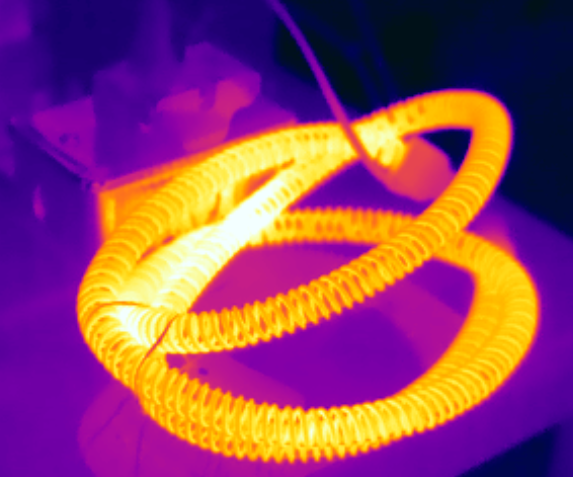

Aptyx worked with the customer’s team to identify issues and brainstorm and evaluate solutions. Aptyx engineers then developed a concept for an innovative heated breathing circuit: a hose constructed with a series of helixes with a wire placed under each helix. This design ensured that neither wire could short circuit the other, addressing safety concerns. The novel design also created a unique intellectual property opportunity.

The Aptyx team had the expertise and technology to manufacture a hose; however, the team had not produced a hose with this new helix geometry. The team created an internal process exclusively for this project, including the extrusion technology, manufacturing equipment, manufacturing process, and testing and validation.

The team developed extrusion tooling and prototyped the product concept. Once they had optimized the hose geometry, team members added wire to the hose and tested the product. They then got to work on optimizing the product development and manufacturing processes to meet the customer’s criteria.

Outcome

The product functioned as expected and reduced condensation in the respiratory circuit so significantly that a water trap was no longer needed, which improved patient safety and enhanced therapy and customer experience.

First, the unique helix design separating the wires eliminated the risk of short circuit. Second, eliminating the need for a water trap removed the opportunity for contamination. Third, eliminating the water trap that needs regular draining both improved patient experience and required less monitoring and intervention from healthcare providers, which increased efficiency and saved time and cost.

This was a win for the customer, as it allowed them to enter a new market, improve the patient and healthcare provider experience, and gain significant market share.

Aptyx has continued to work with this customer and has developed several iterations of this unique circuit concept, including a miniaturized neonatal version. The Aptyx team continues to collaborate with this customer on new product innovations to enhance patient outcomes.