Customer Situation

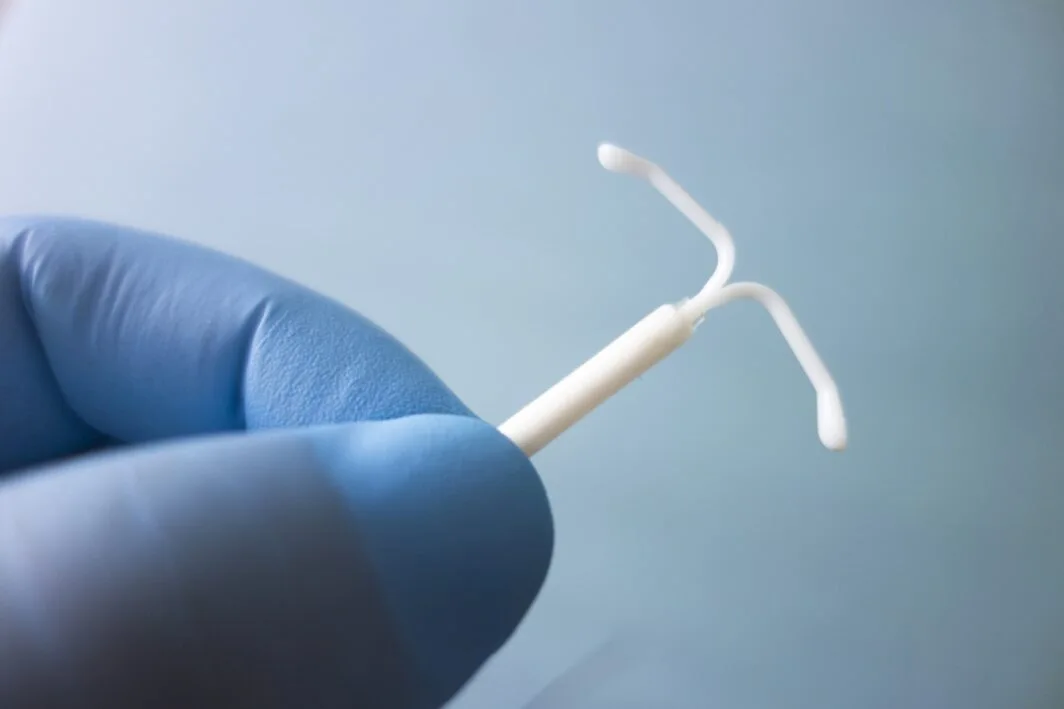

A multinational pharmaceutical and biotechnology company partnered with Aptyx to improve the accuracy of the delivery mechanism for a contraceptive device that releases a drug over an extended period of time. The drug delivery mechanism was a material that came to Aptyx in bulk format, as a continuous spool.

Aptyx Solution

To develop a coating solution, Aptyx team members considered factors such as the absorption rate of the material, the rate at which it could be fed through the coating machine, and the consistency of the coating. They also had to monitor the speed, drying conditions, and diameter of the material to ensure all parameters were within specification.

The greatest challenge was designing and building a live, dynamic visual inspection system that could determine whether the coating was properly applied to the substrate, which had some manufacturing variation. The material went through a series of cameras capable of precisely comparing the substrate’s pre-coat geometry with the post-coat geometry based on exact position. Any areas where substrate variation or coating changes caused improper coating were cut out of the spool.

Outcome

The team devised a novel process to precisely, evenly apply the coating to the material to ensure accurate, dependable drug release over time, consistent with product guidelines.

The solution also enabled the material to be respooled after coating so it could be sent to assembly, without affecting the downstream manufacturing process. In addition, the coating was fully traceable throughout the product lifecycle to comply with FDA regulations for pharmaceutical products.