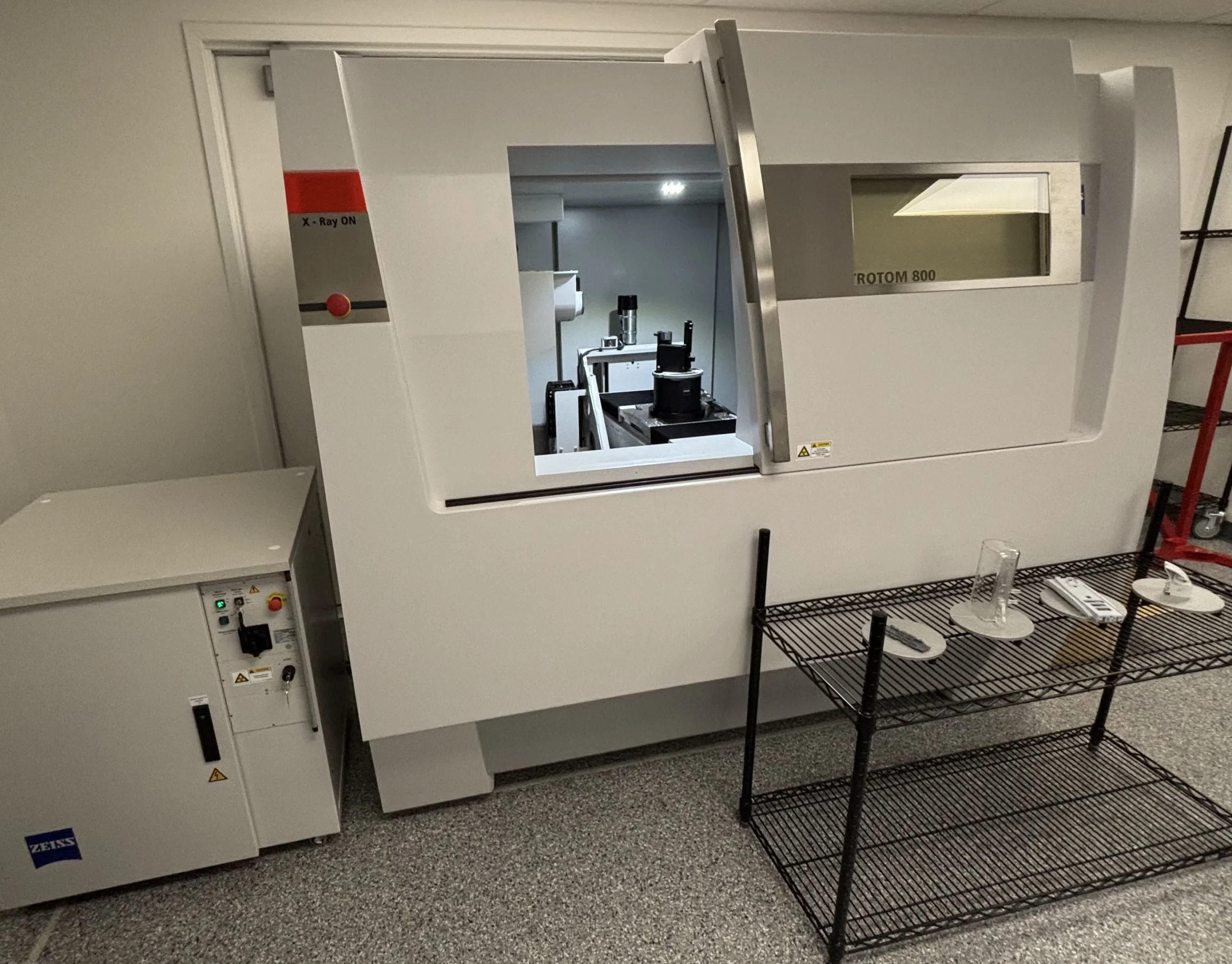

At Aptyx, we’re driven by a culture of continuous improvement and committed to investing in technologies that enhance our capabilities and bring greater value to our customers. That’s why we’re excited to announce the addition of a new Zeiss CT scanner at our Torrington, CT location. This powerful tool represents a significant leap forward in how we inspect, validate, and refine medical device components—and it’s set to benefit not just Torrington but our entire network of manufacturing sites.

What Makes the CT Scanner a Game-Changer?

CT (Computed Tomography) scanning is becoming the new standard in high-precision measurement and analysis for medical device manufacturing. Unlike traditional inspection methods that are limited to surface measurements or destructive testing, our CT scanner uses X-rays to generate high-resolution 3D images of both the internal and external geometries of molded parts.

Here’s why that matters:

1. Non-Destructive Testing

With CT, we can inspect internal structures without cutting or damaging the part. This is vital for medical devices where structural integrity and exact tolerances are non-negotiable.

2. Faster, More Comprehensive Measurements

Scans take about one second to produce—and while analysis can take longer, the system can scan multiple parts at once, dramatically increasing throughput and reducing bottlenecks compared to conventional CMM or vision systems, which typically handle one part and one measurement at a time.

3. Accelerated Problem-Solving

CT scanning excels at uncovering hidden defects—such as voids, cracks, or inclusions—that could affect performance or compliance. This leads to faster root cause analysis and quicker decision-making during molding, process development, and troubleshooting.

4. Supports Complex Part Verification

Whether it’s verifying wall thickness, detecting minuscule dimensional deviations, or assessing intricate internal assemblies, our CT scanner enables data-rich inspections that are critical in the development of sophisticated medical devices.

5. Gear Measurement Capability

Our system includes specialized capabilities to precisely measure injection-molded gears, supporting improved quality and performance in gear-based applications such as robotic and minimally invasive surgery instruments, infusion pumps and other drug delivery devices and more.

6. Enables Reverse Engineering & Regulatory Documentation

Need to replicate a legacy part or validate compliance with FDA or ISO standards? CT-generated models offer accurate, digital blueprints and detailed inspection reports to support design updates and regulatory submissions.

Driving Industry Trends Forward

Traditional CMM metrology—while reliable—is often slow and can cause delays in product development. Across the medical device industry, there’s a growing need for speed, precision, and confidence in data. Our integrated approach, combining CT scanning with CMM, vision, and other tools, ensures a data-driven, reliable, and efficient workflow from the start.

Manufacturers that adopt CT scanning (or partner with those who do) gain a competitive edge by accelerating time to market and improving product quality without compromising safety or compliance.

Aptyx’s Vision for Better, Smarter Manufacturing

The introduction of our CT scanner is more than just an equipment upgrade—it’s a strategic move toward building smarter, more agile, and more effective manufacturing processes. At Aptyx, we’re not just keeping up with industry standards—we’re helping to set them.

If you’re ready to take advantage of next-level metrology and unlock new possibilities in your product development cycle, connect with us. Let’s explore how our CT scanning capabilities can help bring your medical innovations to life—faster, better, and with greater confidence.