If you’re in engineering or procurement, you know that tooling and molding quotes can vary widely among suppliers—even when the part design stays the same. So how do you know if you’re getting a fair and accurate bid? How can you ensure you’re not comparing apples and oranges?

Accurately comparing quotes means more than just looking at the bottom line. It’s about understanding the underlying cost drivers and making smart, strategic decisions that align with what matters most to you. Whether your priority is lower part cost, reduced capital expenditure (CapEx), or faster time to market, knowing how to decode a quote helps you make informed tradeoffs and choose the right molding partner.

Here’s a breakdown of what influences cost and how to evaluate supplier quotes more effectively.

Step 1: Understand Production Volumes and Mold Cavitation

Why It Matters:

Production volume, cycle time, and mold cavitation affect press time, tooling cost, and resin use—all of which directly impact piece price.

As shown in the chart below, a one-cavity mold with an estimated annual volume (EAV) of one million units would require 75% press utilization. This means a dedicated press and the related overhead for an entire year, which would drive up costs.

Mold Cavitation: Impact on Production

| Mold Cavitation | Cycle Time | Parts Per Hour | Parts Per Year | EAV | Run Hours | Max Press Hours | Press Utilization |

|---|---|---|---|---|---|---|---|

| 1 | 20 | 180 | 1,285,200 | 1,000,000 | 5,556 | 7,140 | 78% |

| 2 | 20 | 360 | 2,570,400 | 1,000,000 | 2,778 | 7,140 | 39% |

| 4 | 20 | 720 | 5,140,800 | 1,000,000 | 1,389 | 7,140 | 19% |

| 8 | 20 | 1440 | 10,281,600 | 1,000,000 | 694 | 7,140 | 10% |

| 16 | 20 | 2880 | 20,563,200 | 1,000,000 | 347 | 7,140 | 5% |

| 32 | 20 | 5760 | 41,126,400 | 1,000,000 | 174 | 7,140 | 2% |

The same EAV using a 32-cavity mold would require only 174 hours, which would make your piece part price significantly less. However, there’s a greater tooling investment up front.

For Aptyx as a molding partner, the key is understanding customer needs. While one customer might choose to make a larger initial investment to lower the piece part price, another might prefer to spread the cost more evenly throughout the project. The goal is to balance the upfront CapEx with the optimal piece part price.

Key Factors to Watch:

- Operator load: More manual labor drives up costs.

- Cavitation: More cavities can mean less press utilization and lower part cost, but higher upfront tooling expense.

- Runner system: Cold runners are less costly to build but increase scrap and can increase cycle time. Hot runners are more efficient but more costly up front.

- Mold size and complexity: Complex parts require larger presses and longer cycle times and often yield higher scrap.

- Material efficiency: Low-volume runs don’t benefit from resin price breaks.

Checklist for Comparing Bids

Ask each supplier for:

✓ Cavitation assumptions

✓ Mold function description

✓ Resin feed system (hot or cold runner)

✓ Cycle time estimate

✓ Scrap rate

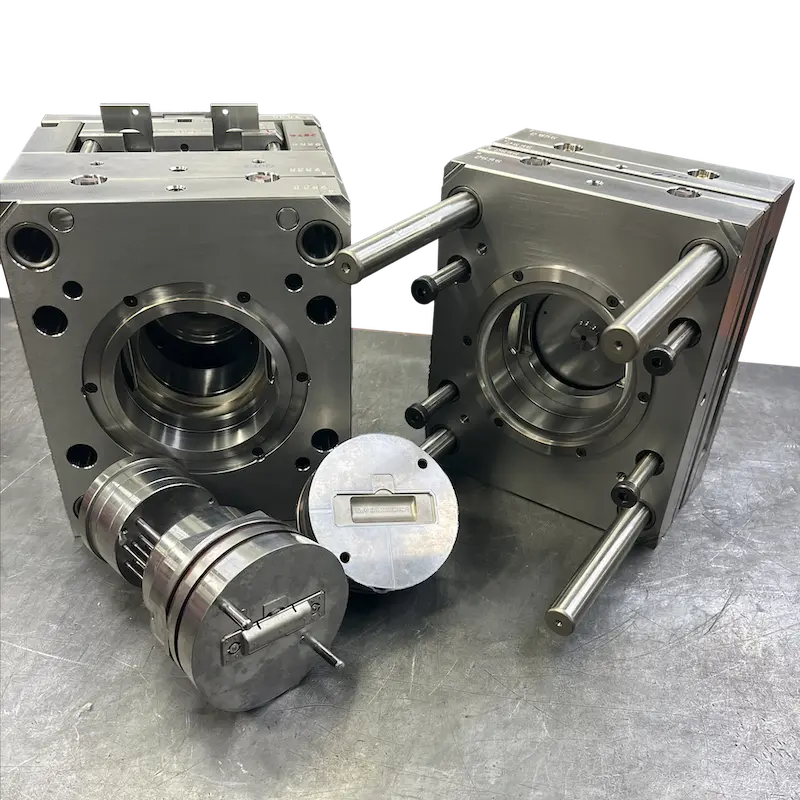

Step 2: Know What SPI Mold Class You’re Getting

SPI Mold Classification

| SPI Class 101 | SPI Class 102 | SPI Class 103 | SPI Class 104 | SPI Class 105 | Aptyx Q-Drive Mold System |

|---|---|---|---|---|---|

| Cycles: ≥ 1 million | Cycles: < 1 million | Cycles: < 500,000 | Cycles: < 100,000 | Cycles: < 500 | Cycles: ≥ 250,000 |

| Extremely high production | Medium–high production | Low–medium production | Low production | Prototype only | Prototype to bridge to low–medium production |

| Prehard stainless mold base | Prehard stainless mold base | Prehard stainless mold base | Mold base mild steel or aluminum | Mold base mild steel or aluminum | Run in proprietary Aptyx 420 Stainless Steel mold base with option to purchase frame |

| Molding surfaces minimum harness 48 RC | Molding surfaces harness 48 RC | Molding surfaces ≥ 28 RC | Cavities aluminum, mild steel or other materials | Hardened cavity & core steel to RC 54–56 | |

| Advanced cooling system design | Good for abrasive materials or high-tolerance parts | Good for non-abrasive materials | |||

| Inserts plated for extended wear protection and corrosion resistance |

Why It Matters:

Different mold classes are designed for different lifespans and use volumes. A quote for a Society of the Plastic Industry (SPI) Class 101 high-volume production mold will look very different from a Class 105 prototype mold.

Our engineering team is always thinking ahead to the requirements of a high-volume production tool, then working backwards to the prototype. Where is the gating going to be? How will the parts be ejected? What’s the best cooling solution to minimize cycle time? This helps us learn what part design changes are needed earlier in the process, leading to a smooth transition from pilot into production.

You can learn many lessons from a prototype if you view it through the lens of long-term production. Designing and building your prototype with the partner you plan to work with for high-volume production can also maximize learning.

Evaluate Based On:

- Annual volume targets

- Intended use: Prototype, pilot, or production

- Material abrasiveness

- Mold function complexity

Checklist for Comparing Bids

✓ Ensure each quote specifies SPI mold class

✓ Confirm material type and lifetime expectations for the tool

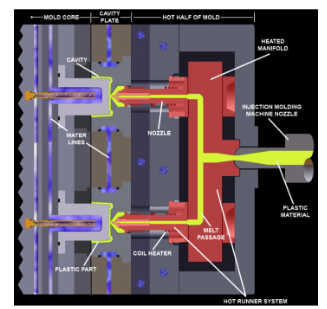

Step 3: Evaluate the Gating Strategy

Why It Matters:

The gating strategy (how the hot resin enters the cavity) directly affects part quality, material efficiency, cycle time, and overall cost. It’s one of the most technically significant and commonly misunderstood differences between supplier quotes.

A supplier quoting a cold runner system will typically show a lower upfront tooling cost, but it may drive up your piece price and operational costs over the life of the project. Conversely, a hot runner system may have a higher initial price tag, but can result in lower total cost of ownership for high-volume runs.

Our engineers help customers understand the pros and cons of gating options to help them select the optimal method for their production goals.

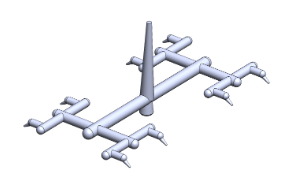

Cold Runner System

Cold Runner Pros and Cons

Pros:

- Lower tooling cost

- Lower maintenance cost

- Faster lead time

Cons:

- Higher piece part price

- Increased scrap

- Slower cycle time

- Lower gate quality

Hot Runner System

Source: Keyarts at English Wikipedia, CC BY-SA 3.0 <https://creativecommons.org/licenses/by-sa/3.0>, via Wikimedia Commons

Hot Runner Pros and Cons

Pros:

- Lowest piece part price

- Faster cycle time

- Better gate aesthetics

- Lower scrap rate

Cons:

- Higher upfront mold cost

- Longer build time

- Larger mold size

- More complex maintenance

Checklist for Comparing Bids

✓Confirm gating type

✓Ask about:

✓ Cycle time

✓ Automation requirements

✓ Labor estimates per part

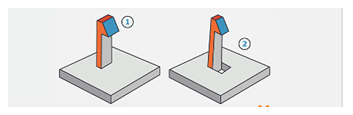

Step 4: Assess Mold Function and Ejection Mechanisms

Why It Matters:

Complex part geometry or additional mold actions (slides, lifters, unscrewing, etc.) requires specialty mold functions to eject parts, which can significantly increase cost, scrap rates, maintenance, and lead time, as well as requiring a larger press. Stacked tolerances from multiple mold elements can reduce the dimensional accuracy of the part.

This is where design for manufacturability (DFM) comes in. We’ve found that when we’re involved early in the design process, our engineers can often propose creative solutions that minimize mold actions, which can reduce tool and part pricing.

Example: Snap Hook Mold

Figure 1: This snap hook would require a lifter or a slide to eject the part because the area shown in blue is “trapped” in the mold.

Figure 2: Designing a simple mold with an opening to allow the blue part to be easily removed with no moving parts can reduce complexity and cost.

Factors That Influence Cost:

- Part geometry and mold actions

- Ejection strategy

- Cooling system design

- Tolerance stack-ups

Checklist for Comparing Bids

✓ Request a detailed mold function description

✓ Ask about alternatives to reduce complexity or cost

Final Thoughts

When developing your request for quote (RFQ), be explicit about your priorities—whether you’re focused on minimizing piece price, reducing upfront CapEx, or accelerating time to production. Clarity helps suppliers tailor their quotes to what matters most to you.

Optimize Part and Mold Designs

- Design with high-volume production in mind

- Minimize mold actions and simplify gating strategies to reduce tool and part pricing

- Designs need to achieve technical requirements while balancing short- and long-term costs

Make Apples-to-Apples Comparisons

- Standardize the quote request: Use a uniform RFQ template that includes expected EAV, SPI mold class, runner preference, gating strategy, and mold complexity expectations.

- Ask for a full cost breakdown: Include tooling cost, estimated cycle time, press size, piece price, and assumed scrap rate.

- Review technical assumptions: Don’t just look at price—understand how each supplier plans to achieve it.

- Validate lifetime and maintenance: A cheaper tool might not survive your expected production run.

Bottom Line

When reviewing tooling and molding bids, price alone isn’t the full story. Dig into the assumptions, ask the right questions, and ensure your comparisons reflect true technical parity. It’s not just about making an accurate comparison—it’s about understanding the cost drivers behind each quote and making informed choices that align with your goals. That’s how smart teams make confident, value-driven supplier decisions.